Understanding the density of a cylinder is crucial in various fields, from engineering to material science. Archimedes, a renowned Greek mathematician, significantly contributed to our understanding of density, influencing the methodology used today. Specifically, knowing the dimensions and mass is an important characteristic of a cylinder, and essential for calculating its density. For example, a 3D printer filament‘s density properties directly impact the final product’s weight and strength. Finally, a precise density of a cylinder calculation is pivotal for quality control and predicting structural behavior in Manufacturing processes.

Density. It’s a fundamental property of matter, a silent dictator governing how materials behave and interact with the world. From the buoyancy of a ship to the structural integrity of a skyscraper, density plays a critical, often unseen, role. Understanding density is crucial in fields ranging from engineering and materials science to everyday applications.

But what exactly is density, and why should we care about the density of a specific shape like a cylinder?

Density: The Essence of "Stuff-ness"

At its core, density is a measure of how much "stuff" is packed into a given space. It quantifies the relationship between an object’s mass (the amount of matter it contains) and its volume (the amount of space it occupies). A dense object, like a lead weight, contains a lot of mass crammed into a small volume. Conversely, a less dense object, like a feather, has relatively little mass spread out over a larger volume.

Density is often expressed as mass per unit volume, such as grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). This provides a standardized way to compare the "compactness" of different materials.

The Cylinder’s Tale: A Shape of Significance

While density is a universal concept, understanding the density of specific shapes is essential in many practical applications. The cylinder, with its simple yet versatile geometry, is a particularly important example. Cylinders are ubiquitous in engineering and manufacturing, appearing in everything from pistons and pipes to structural supports and storage tanks.

Knowing the density of a cylindrical component allows engineers to calculate its mass, predict its behavior under stress, and ensure its suitability for a given application. For example, determining the density of a steel pipe is crucial for calculating its weight and ensuring that the support structures can bear the load.

Your Comprehensive Guide to Cylinder Density

This article serves as your comprehensive guide to understanding and calculating the density of cylinders. We will break down the concepts into manageable steps, providing clear explanations and practical examples.

Our objective is to empower you with the knowledge and tools necessary to accurately determine the density of any cylinder, regardless of its material or dimensions. Whether you’re a student, an engineer, or simply curious about the world around you, this guide will equip you with a solid understanding of cylinder density and its real-world applications. Let’s dive in and unlock the secrets of this fundamental property!

Fundamentals First: Defining Cylinders and Density

Knowing the density of a shape such as a cylinder unlocks a deeper understanding of its properties and behavior. But before we delve into the calculations, it’s crucial to establish a solid foundation by defining the key concepts: what exactly is a cylinder, and what does density mean in practical terms?

Defining the Cylinder: A Geometric Foundation

At its most basic, a cylinder is a three-dimensional geometric shape with two parallel circular bases connected by a curved surface.

Think of a can of soup or a stack of coins – these are everyday examples of cylinders.

Key Properties of a Cylinder

To fully describe a cylinder, we need to understand its essential properties:

-

Radius (r): The distance from the center of the circular base to any point on its circumference. Both bases have the same radius.

-

Height (h): The perpendicular distance between the two circular bases. This is sometimes referred to as the length of the cylinder.

-

Circular Base: The two identical circular ends of the cylinder. These bases are parallel to each other.

These three properties—radius, height, and the circular base—completely define the geometry of a cylinder, allowing us to calculate its volume and, ultimately, its density.

Density: Mass Meets Volume

Density, in its simplest form, is a measure of how tightly matter is packed into a given space.

It’s a fundamental property that relates an object’s mass to its volume.

Mathematically, density is defined as:

Density = Mass / Volume

This means that an object with a high density contains a large amount of mass within a small volume, while an object with a low density contains less mass in the same volume.

Imagine holding a small lead weight and a similarly sized piece of wood. The lead weight feels much heavier because it is significantly denser.

Density is typically expressed in units of mass per unit volume, such as grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³).

The Practical Relevance of Cylinder Density

Understanding the density of cylinders isn’t just an academic exercise; it has numerous practical applications across various fields:

-

Engineering: Engineers use cylinder density to calculate the weight and stability of structures, design pressure vessels, and select appropriate materials for various applications.

-

Manufacturing: In manufacturing, density is crucial for quality control, ensuring that materials meet specific requirements and that products are consistent.

-

Material Science: Scientists use density to characterize and identify different materials, as well as to study their properties and behavior.

-

Fluid Mechanics: The density of cylindrical objects is critical in understanding their behavior in fluids, such as buoyancy and drag.

From designing stronger bridges to creating more efficient engines, knowing the density of cylinders allows us to make informed decisions and build better products. It’s a critical parameter that impacts performance, safety, and efficiency.

Knowing the cylinder’s radius and height, and understanding the concept of density, sets the stage for the actual calculation. Now, let’s uncover the mathematical tools that allow us to quantify these properties and determine the density of a cylinder.

The Formula Unveiled: Calculating Cylinder Volume and Density

At the heart of determining a cylinder’s density lies a simple yet powerful pair of formulas.

These formulas allow us to move from measurable dimensions to a quantifiable density value. Let’s break them down.

Unveiling the Volume Formula: V = πr²h

The volume of a cylinder is calculated using the formula:

V = πr²h

Where:

- V represents the volume of the cylinder.

- π (Pi) is a mathematical constant, approximately equal to 3.14159.

- r is the radius of the circular base.

- h is the height of the cylinder.

This formula reveals that the volume is directly proportional to both the square of the radius and the height.

A larger radius dramatically increases the volume, while a greater height proportionally increases it.

The value of Pi (π) is constant; it’s the ratio of any circle’s circumference to its diameter.

Understanding this relationship is key to accurately calculating the volume.

Decoding the Density Formula: ρ = m/V

Density is calculated using the formula:

ρ = m/V

Where:

- ρ (rho) represents the density of the material.

- m is the mass of the cylinder.

- V is the volume of the cylinder, as calculated previously.

This formula highlights that density is the ratio of mass to volume.

A higher mass packed into the same volume results in a higher density.

Conversely, if the same mass occupies a larger volume, the density decreases.

It is crucial to measure both mass and volume as accurately as possible for a reliable density calculation.

Understanding the Components and Their Units

To effectively use these formulas, it’s essential to understand each component and its associated units:

Density (ρ)

Density is typically expressed in units of grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). The choice of units depends on the scale of the object being measured.

Volume (V)

Volume is measured in cubic units, such as cubic centimeters (cm³) or cubic meters (m³). These units represent the three-dimensional space occupied by the cylinder.

Mass (m)

Mass is a measure of the amount of matter in an object and is typically expressed in grams (g) or kilograms (kg).

Radius (r)

The radius is a linear measurement, usually expressed in centimeters (cm) or meters (m).

Height (h)

Similar to the radius, the height is a linear measurement and is expressed in the same units (cm or m).

Pi (π)

Pi is a dimensionless constant, meaning it has no units associated with it. It’s simply a numerical value (approximately 3.14159).

By understanding the components of these formulas and their corresponding units, you can confidently calculate the density of any cylinder, provided you have accurate measurements of its radius, height, and mass.

Knowing the cylinder’s radius and height, and understanding the concept of density, sets the stage for the actual calculation. Now, let’s uncover the mathematical tools that allow us to quantify these properties and determine the density of a cylinder.

Step-by-Step: A Practical Guide to Calculating Cylinder Density

Calculating the density of a cylinder involves a series of straightforward steps. These steps, when followed meticulously, will provide an accurate density value. Accurate measurements are critical, as even small errors can propagate through the calculations.

Let’s break down the process:

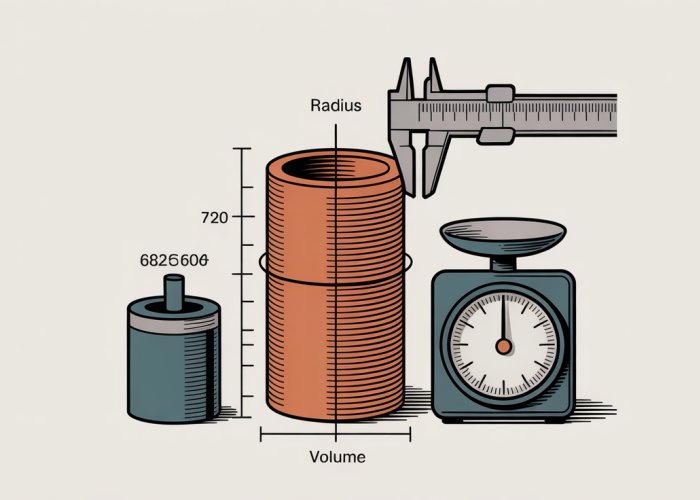

Step 1: Measuring the Radius (r) and Height (h)

The foundation of accurate density calculation lies in precise measurements of the cylinder’s dimensions.

Radius (r) and height (h) are the key parameters needed for the volume calculation.

Tools for Accurate Measurement

- Calipers: Ideal for measuring the diameter of the circular base with high precision. Divide the diameter by two to obtain the radius. Digital calipers offer enhanced accuracy and ease of reading.

- Rulers or Measuring Tapes: Suitable for measuring the height of the cylinder. Ensure the ruler or tape is aligned straight along the cylinder’s axis to avoid parallax errors.

Best Practices for Precise Measurement

- Take multiple measurements at different points along the circumference and height. This helps to account for any irregularities in the cylinder’s shape.

- Calculate the average of these measurements to minimize the impact of individual errors.

- Ensure the cylinder is placed on a flat, stable surface during measurement to prevent wobbling or tilting.

Step 2: Calculating the Volume (V)

Once you have accurate measurements for the radius and height, the next step is to calculate the cylinder’s volume.

Applying the Formula: V = πr²h

The formula for the volume of a cylinder is:

V = πr²h

Where:

- V = Volume

- π ≈ 3.14159 (Pi)

- r = Radius

- h = Height

Plug in the values you obtained for ‘r’ and ‘h’ into the formula. Remember to square the radius before multiplying by Pi and the height.

Example Calculation

Let’s say our cylinder has a radius of 5 cm and a height of 10 cm.

V = π (5 cm)² (10 cm)

V ≈ 3.14159 25 cm² 10 cm

V ≈ 785.4 cm³

Therefore, the volume of the cylinder is approximately 785.4 cubic centimeters.

Step 3: Measuring the Mass (m)

After calculating the volume, you need to determine the mass of the cylinder.

Selecting Appropriate Scales

- Digital Scales: Offer high precision and are ideal for smaller cylinders.

- Balance Scales: Suitable for larger, heavier cylinders.

Ensuring Accurate Mass Measurement

- Calibrate the scales before use to ensure they are providing accurate readings.

- Place the cylinder gently in the center of the scale platform.

- Wait for the reading to stabilize before recording the mass.

- Make sure the surrounding environment is free from vibrations or drafts.

Step 4: Calculating the Density (ρ)

With the volume and mass determined, you can now calculate the density.

Applying the Formula: ρ = m/V

The formula for density is:

ρ = m/V

Where:

- ρ = Density

- m = Mass

- V = Volume

Divide the mass of the cylinder by its volume to obtain the density.

Example Density Calculation

Suppose the cylinder from our previous example has a mass of 2000 grams.

ρ = 2000 g / 785.4 cm³

ρ ≈ 2.55 g/cm³

Therefore, the density of the cylinder is approximately 2.55 grams per cubic centimeter.

Practical Example: Putting It All Together

Let’s solidify the process with a complete example:

- Cylinder: Aluminum rod

- Measured Radius (r): 2 cm

- Measured Height (h): 15 cm

- Measured Mass (m): 500 grams

-

Calculate Volume:

V = πr²h = π (2 cm)² (15 cm) ≈ 188.5 cm³

-

Calculate Density:

ρ = m/V = 500 g / 188.5 cm³ ≈ 2.65 g/cm³

Therefore, the density of the aluminum rod is approximately 2.65 g/cm³. Note that this value is close to the known density of aluminum (around 2.7 g/cm³). Small discrepancies may arise due to measurement inaccuracies or impurities in the material.

Knowing the cylinder’s radius and height, and understanding the concept of density, sets the stage for the actual calculation. Now, let’s uncover the mathematical tools that allow us to quantify these properties and determine the density of a cylinder.

Units Matter: Ensuring Accuracy in Your Calculations

In the world of density calculations, accuracy is paramount, and the cornerstone of accuracy lies in the consistent and correct handling of units. Mixing units or neglecting conversions can lead to drastically wrong results, rendering your entire calculation invalid. Paying meticulous attention to units is not merely a detail; it’s a fundamental requirement for reliable density determination.

Common Units of Density

Density, being mass per unit volume, is expressed using a variety of units, the most common of which include:

-

Grams per cubic centimeter (g/cm³): Often used for smaller objects or materials with relatively low density.

-

Kilograms per cubic meter (kg/m³): The standard unit in the International System of Units (SI), frequently used for larger objects or bulk materials.

-

Pounds per cubic foot (lb/ft³): A unit commonly used in the United States customary system.

Understanding the context of your problem will often dictate which unit is most appropriate. However, consistency is key – ensure you’re using the same unit system for all measurements within a single calculation.

The Importance of Unit Consistency

Imagine calculating the volume of a cylinder using a radius measured in centimeters and a height measured in meters. Directly plugging these values into the volume formula (V = πr²h) will produce an incorrect result because the units are incompatible. You must convert both measurements to the same unit before proceeding.

Failing to maintain consistent units is a common source of error, even for experienced professionals. Always double-check your units at each step of the calculation to prevent such mistakes.

Converting Between Units

The ability to convert between different units of measurement is essential for accurate density calculations. Here’s a brief overview of common conversions:

- Grams (g) to Kilograms (kg): Divide by 1000 (1 kg = 1000 g).

- Cubic Centimeters (cm³) to Cubic Meters (m³): Divide by 1,000,000 (1 m³ = 1,000,000 cm³).

- Pounds (lb) to Kilograms (kg): Multiply by approximately 0.453592 (1 kg ≈ 2.20462 lb).

- Cubic Feet (ft³) to Cubic Meters (m³): Multiply by approximately 0.028317 (1 m³ ≈ 35.3147 ft³).

Example: Converting g/cm³ to kg/m³

To convert a density value from g/cm³ to kg/m³, multiply by 1000.

For example, the density of aluminum is approximately 2.7 g/cm³. To convert this to kg/m³:

- 7 g/cm³ * 1000 = 2700 kg/m³

Tools for Unit Conversion

Numerous online unit conversion tools and calculators can assist with unit conversions. However, it’s crucial to understand the underlying principles of conversion to avoid blindly relying on these tools. Always verify the results obtained from online converters to ensure accuracy.

Best Practices for Unit Management

To minimize errors related to units, adopt these best practices:

- Always write down the units alongside every measurement and calculated value.

- Clearly indicate the units in your formulas and equations.

- Perform unit conversions at the beginning of the calculation to ensure consistency.

- Double-check your units at each step to identify potential errors.

- Use dimensional analysis to verify that your calculations are dimensionally consistent.

By diligently following these guidelines, you can significantly reduce the risk of errors related to units and ensure the accuracy of your density calculations.

Imagine your density calculation is perfectly executed, adhering to all the formulas and unit conversions. However, if you’ve overlooked the inherent properties of the material itself, or the environmental conditions surrounding it, your result might still deviate from reality. Density isn’t merely a mathematical abstraction; it’s a physical property influenced by a variety of real-world factors.

Factors Influencing Density: Material, Temperature, and Pressure

The density of a cylinder, while seemingly straightforward to calculate, is not a fixed, immutable value. Several factors can cause it to fluctuate, sometimes significantly. Understanding these influences is crucial for accurate density determination and practical application. The primary influencers are the material composition, temperature, and pressure.

Material Matters: Density as an Intrinsic Property

The fundamental building block of a cylinder, its constituent material, is the most significant determinant of its density. Different materials possess inherently different atomic structures and molecular packing arrangements, leading to vast disparities in mass per unit volume.

For instance, consider three cylinders of identical dimensions, one made of aluminum, one of steel, and one of wood.

Steel will invariably exhibit the highest density, followed by aluminum, with wood possessing the lowest. This is because steel’s atomic structure allows for a much greater mass to be packed into the same volume compared to aluminum and wood.

Reference tables listing the densities of various materials under standard conditions (typically 20°C and 1 atmosphere of pressure) are readily available and serve as valuable benchmarks. However, remember that these are reference points.

Temperature’s Subtle Shift: Thermal Expansion and Contraction

Temperature plays a crucial role in influencing density through the phenomenon of thermal expansion and contraction. As temperature increases, the kinetic energy of the atoms or molecules within a substance also increases.

This heightened energy leads to greater atomic separation, causing the material to expand in volume. Since density is inversely proportional to volume (ρ = m/V), an increase in volume due to thermal expansion results in a decrease in density, assuming the mass remains constant.

Conversely, a decrease in temperature causes the material to contract, reducing its volume and increasing its density.

The extent of thermal expansion or contraction varies depending on the material’s coefficient of thermal expansion. Materials with high coefficients of thermal expansion, such as aluminum, exhibit more pronounced density changes with temperature fluctuations compared to materials with low coefficients, such as steel.

Therefore, precise temperature control is critical when measuring the density of materials with high thermal expansion coefficients or when comparing density values obtained at different temperatures.

Pressure’s Compressive Force: Minimal Impact, Notable Exceptions

Pressure, defined as force per unit area, can also influence density, particularly in compressible materials. Applying external pressure to a cylinder compresses its volume, forcing the constituent atoms or molecules closer together. This compression leads to an increase in density.

However, for most solid materials, including common metals and woods used in cylinder construction, the effect of pressure on density is generally negligible under normal atmospheric conditions.

The change in density becomes significant only under extremely high pressures, such as those encountered in deep-sea environments or industrial processes. Compressible materials like gases exhibit a much more pronounced density change with pressure variations, governed by the ideal gas law and related equations of state.

Uniform vs. Variable Density: A Matter of Homogeneity

While we often assume a uniform distribution of mass throughout a cylinder, this isn’t always the case. A cylinder is said to have uniform density when its mass is evenly distributed throughout its volume. Meaning any sample taken from that object would have the same density as the whole.

However, some cylinders may exhibit variable density, where the density varies from one point to another. This can occur due to several factors, including:

- Material Composition Variations: Inhomogeneous mixtures of different materials within the cylinder.

- Manufacturing Defects: Voids, inclusions, or density gradients introduced during the manufacturing process.

- External Factors: Uneven heating or compression leading to localized density changes.

In cases of variable density, determining the average density of the cylinder requires more sophisticated techniques, such as dividing the cylinder into smaller segments and measuring the density of each segment individually or employing non-destructive testing methods like X-ray computed tomography.

Imagine your density calculation is perfectly executed, adhering to all the formulas and unit conversions. However, if you’ve overlooked the inherent properties of the material itself, or the environmental conditions surrounding it, your result might still deviate from reality. Density isn’t merely a mathematical abstraction; it’s a physical property influenced by a variety of real-world factors.

Taking our understanding of density beyond theoretical calculations, we now turn our attention to its practical applications. Why does knowing the density of a cylinder matter in the real world? The answer lies in its widespread use across diverse fields, where it plays a crucial role in design, manufacturing, and analysis.

Real-World Applications: Why Cylinder Density Matters

The density of a cylinder, and indeed of any object, isn’t just a number to be calculated and forgotten. It’s a fundamental property that informs critical decisions in various industries. From ensuring structural integrity in engineering projects to selecting the right materials for manufacturing processes, understanding cylinder density is paramount.

Engineering Design and Structural Integrity

In engineering, the density of cylindrical components is a vital consideration for structural design. Engineers need to know the density of materials used in load-bearing cylindrical structures like pillars, support beams, and pressure vessels.

Knowing the density allows engineers to accurately calculate the weight of these components, which is crucial for determining the overall stability and load-bearing capacity of the structure.

For example, when designing a cylindrical support column for a bridge, engineers must consider the density of the concrete or steel used. This information helps them predict how the column will respond to various loads, ensuring the bridge’s safety and longevity. Similarly, in aerospace engineering, the density of cylindrical components in aircraft landing gear is critical for assessing its strength and resistance to impact forces.

Material Selection and Optimization

Density plays a key role in the selection of materials for specific applications. Engineers often face the challenge of choosing the most suitable material for a cylindrical component based on its required strength, weight, and cost.

Density serves as a crucial factor in this decision-making process.

For instance, in the automotive industry, engineers might choose aluminum over steel for certain cylindrical engine components to reduce the overall weight of the vehicle, improving fuel efficiency. The lower density of aluminum, compared to steel, allows for a lighter component without sacrificing structural integrity.

Conversely, in applications where high strength and durability are paramount, such as in heavy machinery, steel might be preferred despite its higher density.

Quality Control in Manufacturing

Density measurements serve as a powerful tool for quality control in manufacturing processes involving cylindrical products. By accurately determining the density of manufactured cylinders, companies can ensure that they meet the specified material composition and dimensional tolerances.

Deviations from the expected density can indicate defects such as voids, inclusions, or variations in material composition.

Imagine a manufacturer producing cylindrical metal rods. By measuring the density of each rod, they can quickly identify any rods that are not within the specified density range. These outliers might indicate the presence of impurities or inconsistencies in the manufacturing process, prompting corrective actions to maintain product quality.

Practical Problem Solving with Density Calculations

Density calculations are not limited to theoretical exercises; they are often used to solve real-world practical problems.

For example, consider a scenario where you need to determine the material of an unknown cylindrical object. By accurately measuring its dimensions and mass, you can calculate its density and compare it to the known densities of various materials.

This comparison can help you identify the material composition of the cylinder. Similarly, density calculations can be used to determine the volume of irregular shaped objects by immersing them in a fluid within a graduated cylinder and measuring the displacement, another application showcasing the versatility of density in practical problem solving.

In essence, the density of a cylinder is more than just a calculated value. It’s a fundamental property that provides critical insights into its composition, behavior, and suitability for various applications. Understanding and applying density calculations allows engineers, manufacturers, and scientists to make informed decisions, optimize designs, and ensure the quality and reliability of cylindrical components in numerous real-world scenarios.

Cylinder Density FAQs

Here are some frequently asked questions regarding cylinder density calculation, designed to clarify the process and ensure you can confidently apply the formula.

What exactly is cylinder density?

Cylinder density is a measure of how much mass is contained within a cylinder’s volume. It’s a fundamental property that describes how tightly packed the matter is in that specific cylinder. This is critical in a variety of scientific and engineering applications.

How is the density of a cylinder calculated?

The density of a cylinder is calculated by dividing its mass by its volume. The formula is: Density = Mass / Volume. Make sure your units are consistent (e.g., grams for mass, cubic centimeters for volume) to obtain the density in grams per cubic centimeter (g/cm³).

What units are typically used for cylinder density?

Common units for density include grams per cubic centimeter (g/cm³), kilograms per cubic meter (kg/m³), and pounds per cubic foot (lb/ft³). The appropriate unit will depend on the scale of the cylinder and the context of the calculation. Always double-check units.

Why is understanding the density of a cylinder important?

Knowing the density of a cylinder allows you to predict its behavior in different situations, such as buoyancy or how it interacts with other materials. It’s essential for material selection in engineering, determining the weight of cylindrical components, and many other practical applications.

So there you have it! Calculating the density of a cylinder doesn’t have to be a headache. Now you’ve got the tools – go forth and measure!