Ensuring a secure and level subfloor is crucial for any successful flooring installation. Proper OSB underlayment fastener pattern is paramount in achieving this goal. Ignoring best practices can lead to significant problems later on. The National Wood Flooring Association (NWFA) provides detailed guidelines on fastener spacing. These guidelines ensure adequate support, preventing movement and squeaks. Selecting the correct fastener type such as screws or staples plays an important role. Using the right osb underlayment fastener pattern with appropriate fasteners and by following NWFA standards will result in floors that are stable and long-lasting.

A beautiful new floor can transform a space, adding value and comfort to your home or business. However, the longevity and appearance of that floor depend heavily on what lies beneath – specifically, the underlayment and its proper installation.

Oriented Strand Board (OSB) has become a widely used underlayment material, prized for its cost-effectiveness and structural properties. But its performance hinges on one often-overlooked detail: the fastener pattern.

A seemingly minor aspect of installation, the fastener pattern – the spacing and placement of nails, screws, or staples – is, in reality, a critical factor in ensuring a floor that remains flat, quiet, and beautiful for years to come.

OSB: A Common Foundation

OSB is engineered from strands of wood, compressed and bonded together with adhesives. It provides a solid, even surface upon which the finished flooring material is installed.

Its affordability and availability have made it a popular choice for both new construction and renovation projects. However, its inherent properties require careful attention to installation techniques.

The Undervalued Fastener Pattern

Imagine spending a significant amount on premium hardwood, tile, or laminate, only to find that, within a few years, your floor is riddled with squeaks, uneven surfaces, or even loose boards.

More often than not, the culprit is a faulty fastener pattern in the OSB underlayment. An incorrect pattern creates weak points, allowing movement and flexing that ultimately compromise the entire flooring system.

The fastener pattern isn’t just about holding the OSB in place; it’s about distributing stress evenly and preventing the board from warping or buckling in response to changes in humidity and temperature.

Installation Errors: The Seeds of Destruction

Unfortunately, proper fastener patterns are frequently overlooked or executed incorrectly. Common mistakes include:

-

Over-spacing fasteners: This leaves large areas of the OSB unsupported, leading to flexing and potential squeaking.

-

Under-spacing fasteners: While it might seem like "more is better," overcrowding fasteners can weaken the OSB and even cause it to split.

-

Ignoring edge distance: Fasteners placed too close to the edge of the board are prone to pulling through, especially under stress.

-

Using the wrong type of fastener: Not all fasteners are created equal. Using the wrong type can result in inadequate holding power or even damage to the OSB.

These errors, seemingly small on their own, can lead to significant problems down the road. These issues may include uneven flooring, squeaky floors, or even structural damage. By understanding the critical role of fastener patterns and avoiding common mistakes, you can ensure a long-lasting and beautiful floor.

The fastener pattern isn’t just about holding the OSB in place; it’s about distributing stress evenly and preventing movement that can ultimately lead to floor failure. But to fully appreciate the importance of the fastener pattern, we first need to understand what OSB underlayment is, its purpose in the grand scheme of flooring, and how it stacks up against other underlayment options. Let’s lay the groundwork for success by delving into the fundamentals of OSB underlayment.

Understanding OSB Underlayment: What It Is and Why It Matters

Oriented Strand Board (OSB) underlayment forms the critical foundation upon which your finished floor rests. It’s an engineered wood product manufactured from rectangular wood strands arranged in layers, oriented perpendicularly, and bonded together with heat-cured adhesives. This layered construction provides exceptional strength, rigidity, and dimensional stability compared to traditional plywood.

Defining OSB and Its Function in Flooring Systems

OSB’s primary function is to create a smooth, level, and structurally sound surface for installing various floor coverings. It acts as a bridge, distributing the weight and impact forces across the subfloor, protecting the finished flooring from undue stress. A well-installed OSB underlayment prevents deflection, reduces noise transmission, and contributes significantly to the overall comfort and longevity of the floor.

Think of it as the unsung hero beneath your feet, working tirelessly to maintain the integrity of your investment.

OSB vs. Other Underlayment Types: Choosing the Right Foundation

While OSB is a popular choice, it’s essential to consider other underlayment options and understand their suitability for different applications.

-

Plywood: Plywood, another engineered wood product, offers similar benefits to OSB but often comes at a higher cost. While some prefer plywood due to perceived better moisture resistance (depending on the grade), OSB has largely become the standard in many regions due to its cost-effectiveness and consistent performance when properly installed.

-

Cement Board: Ideal for tile and stone installations, cement board provides a waterproof and exceptionally rigid base. However, it’s typically more expensive and requires specialized installation techniques.

-

Self-Leveling Underlayment (SLU): SLU is a pourable compound used to create a perfectly level surface over uneven subfloors. It’s often used in conjunction with other underlayment types, like OSB, to address significant irregularities.

-

Cork Underlayment: Cork provides sound dampening and thermal insulation. It’s often used under laminate or floating floors.

When selecting an underlayment, consider factors like the type of flooring, subfloor condition, moisture levels, and budget. OSB is generally a great choice for a wide range of flooring types, including hardwood, laminate, and carpet, provided it’s installed correctly and the subfloor is relatively level.

The Importance of Choosing the Correct OSB Thickness

Selecting the appropriate OSB thickness is paramount for achieving a stable and long-lasting floor. Thickness is driven by joist spacing: the wider the joist spacing, the thicker the OSB needs to be.

-

Insufficient Thickness: Using OSB that is too thin can lead to deflection, resulting in squeaky floors, uneven surfaces, and premature wear of the finished flooring.

-

Excessive Thickness: While thicker OSB provides greater rigidity, it can also add unnecessary weight and cost to the project. In some cases, it can even create height differences that cause transitions to become necessary where the floor meets other surfaces.

Always consult local building codes and manufacturer recommendations to determine the appropriate OSB thickness for your specific application. Common thicknesses range from 1/2 inch to 3/4 inch, but these can vary based on joist spacing and the type of flooring being installed.

It’s clear that selecting the right OSB underlayment is crucial for a successful flooring project. The choice of underlayment sets the stage, but the unsung heroes (and potential villains) of your floor’s performance are the fasteners that secure it.

Fasteners: The Unsung Heroes (and Villains) of Your Floor

The fasteners you choose for your OSB underlayment are more than just pieces of metal holding things together. They are critical components that influence the floor’s stability, longevity, and overall performance. Selecting the appropriate fastener type and size is a decision that demands careful consideration, as the wrong choice can lead to a cascade of problems down the line.

Suitable Fastener Types for OSB Underlayment

When it comes to securing OSB underlayment, three main types of fasteners typically come into play: nails, screws, and staples. Each has its own set of advantages and disadvantages.

Nails

Nails, particularly ring-shank nails, are a common and relatively inexpensive option. Their ribbed shanks provide increased holding power compared to smooth nails, resisting pull-out forces caused by movement and expansion/contraction.

However, nails can be prone to loosening over time due to vibration and wood movement. They can also cause nail pops in the finished floor covering if not properly installed or if the subfloor isn’t perfectly level.

Screws

Screws, especially self-tapping screws designed for wood, offer superior holding power compared to nails. Their threaded shafts grip the wood fibers tightly, providing excellent resistance to pull-out.

Screws are also less likely to loosen over time and can be easily adjusted or removed if necessary. The primary downside of screws is their higher cost and the longer installation time compared to nails.

Staples

Staples are a fast and efficient option for fastening OSB underlayment, especially when using a pneumatic staple gun. However, staples generally offer the least holding power of the three fastener types.

They are more prone to loosening and may not be suitable for applications where high levels of stress or movement are expected. Using staples requires extra caution to ensure proper penetration and avoid damaging the OSB.

Why Correct Fastener Selection is Vital

Choosing the right fastener is not just a matter of convenience or cost. It’s a critical decision that impacts the structural integrity and long-term performance of your floor. Incorrect fastener selection can lead to a host of problems, including:

- Reduced Holding Power: Insufficient holding power can cause the OSB underlayment to loosen, leading to squeaks, movement, and unevenness in the finished floor.

- Increased Risk of Failure: The wrong fasteners may not be able to withstand the stresses and strains placed on the floor, increasing the risk of delamination, cracking, and other types of failure.

- Compromised Warranty: Many flooring manufacturers specify the type and spacing of fasteners that must be used to maintain the warranty.

The Impact of Incorrect Fasteners

The consequences of using the wrong fasteners can extend beyond the OSB underlayment itself, impacting both the floor covering and the subfloor.

-

Damage to the Floor Covering: If the underlayment is not securely fastened, it can cause the floor covering to shift, crack, or become uneven. Nail pops can protrude through the finished floor, creating unsightly bumps and potential tripping hazards.

-

Damage to the Subfloor: Incorrect fasteners can damage the subfloor by splitting the wood fibers or creating excessive stress points. This can weaken the subfloor and compromise its ability to support the weight of the floor.

-

Long-Term Structural Issues: Over time, using the wrong fasteners can lead to significant structural problems in the floor system. This can result in costly repairs and even require replacing the entire floor.

By understanding the different types of fasteners available and their respective strengths and weaknesses, you can make informed decisions that will contribute to a long-lasting, beautiful, and structurally sound floor. Don’t underestimate the importance of these small components – they play a vital role in the overall success of your flooring project.

It’s clear that selecting the right OSB underlayment is crucial for a successful flooring project. The choice of underlayment sets the stage, but the unsung heroes (and potential villains) of your floor’s performance are the fasteners that secure it. But even the best nails or screws are rendered ineffective without a strategic plan. The secret to a stable, long-lasting floor lies in the fastener pattern.

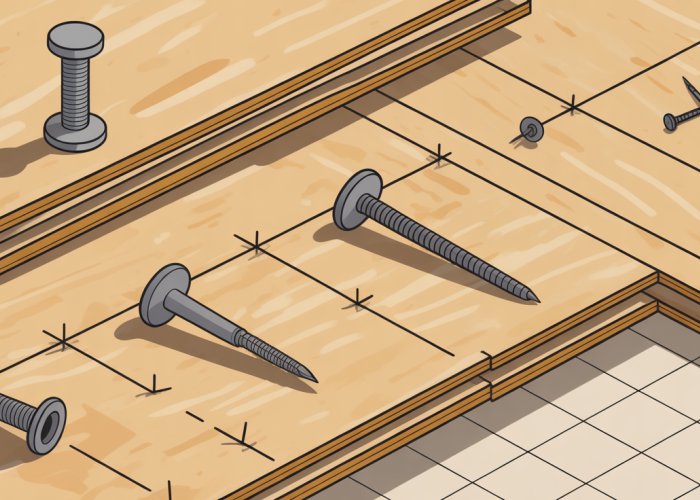

Cracking the Code: The Ideal OSB Underlayment Fastener Pattern

The fastener pattern is the blueprint for securing your OSB underlayment. It dictates the precise spacing between fasteners and the distance from the edges of the OSB sheets. Think of it as a carefully choreographed dance, where each fastener plays a vital role in preventing movement, resisting stress, and ensuring a flat, uniform surface for your finished floor. Understanding and implementing the correct pattern is paramount.

Decoding the Fastener Pattern: Spacing and Edge Distance

Let’s break down the key components of a fastener pattern: spacing and edge distance.

-

Spacing refers to the distance between individual fasteners across the field of the OSB sheet. Proper spacing ensures that the underlayment is uniformly supported and that loads are evenly distributed. Overly wide spacing can lead to flexing and movement, while excessively close spacing can weaken the OSB and increase the risk of splitting.

-

Edge distance is the distance from the edge of the OSB sheet to the nearest fastener. Maintaining the correct edge distance is crucial to prevent the edges from lifting, curling, or becoming damaged. Insufficient edge distance can compromise the integrity of the entire installation.

Fastener Pattern Guidelines Based on OSB Thickness

The optimal fastener pattern is not one-size-fits-all. It depends heavily on the thickness of the OSB underlayment being used. Thicker OSB generally requires less frequent fastening than thinner OSB.

Here are some general guidelines, however, always refer to manufacturer specifications.

For OSB underlayment that is ½" to 5/8" thick, a typical fastener pattern is 6" along the edges and 12" in the field (the central area of the sheet).

For thicker OSB, such as ¾" or greater, you might space fasteners at 8" along the edges and 16" in the field.

These are starting points. Local building codes or specific flooring requirements may dictate different patterns.

Always measure twice and fasten once!

The Importance of Manufacturer Recommendations and Building Codes

While general guidelines can be helpful, the ultimate authority on proper fastener patterns lies with the OSB manufacturer and local building codes.

Manufacturer recommendations are based on rigorous testing and take into account the specific properties of their OSB products. These recommendations will usually specify the type of fastener to be used, along with the required spacing and edge distance.

Local building codes are designed to ensure the safety and structural integrity of buildings. They may have specific requirements for fastener patterns that must be followed, regardless of manufacturer recommendations.

Failing to adhere to these guidelines can result in failed inspections, costly rework, and compromised floor performance. It is always best practice to consult both resources before beginning any installation project. Consider both as equally important as each other.

It’s clear that selecting the right OSB underlayment is crucial for a successful flooring project. The choice of underlayment sets the stage, but the unsung heroes (and potential villains) of your floor’s performance are the fasteners that secure it. But even the best nails or screws are rendered ineffective without a strategic plan. The secret to a stable, long-lasting floor lies in the fastener pattern.

Don’t Do These! Common Fastener Pattern Mistakes to Avoid

Installing OSB underlayment might seem straightforward, but overlooking crucial details in the fastener pattern can lead to significant problems down the line. Many common errors, often born from a desire to save time or cut costs, can severely compromise the integrity and lifespan of your floor. Understanding these pitfalls is the first step toward ensuring a professional and durable installation.

The Perils of Improper Spacing: Too Much or Too Little

Fastener spacing is a balancing act. The goal is to provide adequate support without compromising the structural integrity of the OSB.

Over-spacing, or placing fasteners too far apart, is a frequent mistake. This creates unsupported areas, leading to excessive flexing and movement in the underlayment. Over time, this can cause the flooring to loosen, squeak, or even crack. Think of it like a bridge with too few supports—it will eventually sag and fail.

Under-spacing, on the other hand, involves using too many fasteners in a concentrated area. While it might seem like overkill, excessive fasteners can weaken the OSB. This can lead to splitting or crumbling around the fasteners, reducing their holding power and potentially creating a bumpy, uneven surface. The key is to find the "Goldilocks" zone—spacing that’s just right.

The Wrong Fasteners: A Recipe for Disaster

Using the wrong type of fastener for the OSB thickness is another common and costly mistake. The length and gauge of the fastener must be appropriate for the material to ensure a secure and lasting hold.

Using fasteners that are too short will result in insufficient penetration into the subfloor. This will make them prone to pulling out over time. This is especially true under heavy loads or in areas with high traffic.

Conversely, fasteners that are too long can protrude through the subfloor, creating potential hazards. They also risk interfering with plumbing or electrical systems. Always consult the manufacturer’s recommendations to determine the ideal fastener specifications for your OSB underlayment. Prioritize quality fasteners to avoid corrosion issues that reduce hold strength over time.

Edge Distance Neglect: The Unraveling Begins

The edge distance—the distance from the edge of the OSB sheet to the nearest fastener—is a frequently overlooked aspect of the installation process. However, neglecting this crucial detail can have serious consequences.

Insufficient edge distance is a common blunder. It weakens the edges of the OSB, making them susceptible to lifting, curling, and damage from impact. This is because the edges are the most vulnerable parts of the sheet, and require adequate support.

Ignoring edge distance requirements can lead to significant problems, particularly in high-traffic areas or along walls. In these cases, the edges will begin to deteriorate quickly.

The Ripple Effect: Consequences of Fastener Pattern Errors

Each of these seemingly small mistakes can have a cascading effect on the overall floor installation. Over- or under-spaced fasteners can lead to squeaking floors, uneven surfaces, and premature wear of the floor covering.

Incorrect fasteners can cause structural damage to the subfloor, necessitating costly repairs. Ignoring edge distance requirements can result in unsightly gaps, unstable edges, and an overall unprofessional appearance.

By understanding and avoiding these common fastener pattern mistakes, you can significantly improve the quality and longevity of your floor installation. You’ll also save yourself from potential headaches and expenses down the road.

The High Cost of Cutting Corners: Consequences of a Poor Fastener Pattern

Investing in quality materials and meticulous craftsmanship is paramount when installing flooring. However, even the most beautiful hardwood or luxurious tile can be undermined by a flawed OSB underlayment installation, specifically a poor fastener pattern. Overlooking this crucial detail can lead to a cascade of problems, diminishing the aesthetic appeal and structural integrity of your floors.

The Annoying Symphony: Squeaking Floors

One of the most common and irritating consequences of an inadequate fastener pattern is squeaking floors. This unwelcome noise arises when the OSB underlayment isn’t securely fastened to the subfloor, allowing it to rub against the joists or subfloor with every step.

Insufficient fasteners or improper spacing create unsupported areas, leading to this movement. Over time, this constant friction wears down the materials, exacerbating the squeak and potentially leading to more significant issues.

From Flat to Flawed: Cupping and Uneven Floor Coverings

Beyond the auditory annoyance, a poor fastener pattern can manifest in visible imperfections, such as cupping and uneven floor coverings. When fasteners are spaced too far apart, the edges of the OSB panels may lift or warp, creating an uneven surface.

This is especially problematic with thin or rigid flooring materials like tile or laminate. These materials rely on a perfectly flat and stable subfloor. Any imperfections in the underlayment will telegraph through, resulting in an unattractive and potentially unsafe floor.

Cupping occurs when the edges of individual flooring planks rise slightly higher than their centers, creating a concave appearance. This can be caused by moisture but is also often exacerbated by an uneven underlayment due to poor fastening.

The Unseen Enemy: Expansion and Contraction Issues

Wood and wood-based products naturally expand and contract with changes in humidity. A properly installed OSB underlayment allows for this movement.

However, an inadequate fastener pattern can restrict this natural process, leading to stress within the flooring system. Over-tightening fasteners or using too many in a small area can prevent the OSB from expanding and contracting properly.

This can result in buckling, cracking, or even separation of the flooring material from the underlayment. This is particularly problematic in areas with significant humidity fluctuations.

The Foundation Crumbles: Long-Term Structural Damage

The most severe consequence of a flawed fastener pattern is long-term structural damage to the subfloor. If the underlayment is not securely fastened, it can allow moisture to penetrate and reach the subfloor.

This can lead to rot, mold growth, and weakening of the joists, compromising the entire floor structure. Addressing this type of damage is significantly more expensive and disruptive than correcting a simple squeak or uneven surface.

Ignoring the fastener pattern is a gamble with the long-term health of your floors. Investing the time and effort to ensure a proper installation is a small price to pay for peace of mind and a floor that will stand the test of time.

Cupping and uneven surfaces are just the tip of the iceberg. A poorly executed fastener pattern can also lead to expansion and contraction issues, potentially compromising the structural integrity of the subfloor over time. It’s a domino effect that starts with a seemingly small oversight and ends with significant repair costs and diminished satisfaction.

Beyond the Basics: Factors Influencing Your Fastener Pattern Choice

While the guidelines for fastener patterns based on OSB thickness provide a solid foundation, they aren’t the whole story. Several other factors significantly influence the optimal fastener pattern, demanding a more tailored and nuanced approach to installation. Neglecting these variables can undermine even the most diligent efforts, leading to the very problems you’re trying to avoid.

The Moisture Factor: Adapting to Humidity and Potential Water Exposure

Moisture is a formidable enemy of wood-based products, including OSB underlayment. High humidity levels or potential water exposure can cause OSB to swell, warp, or even delaminate. This movement can compromise the effectiveness of the fastener pattern, potentially leading to loose fasteners and the aforementioned problems like squeaking and unevenness.

In moisture-prone environments, such as bathrooms or kitchens, a tighter fastener pattern is generally recommended. This increased density helps to secure the OSB more firmly, minimizing movement caused by moisture fluctuations.

Consider using moisture-resistant OSB and pairing it with corrosion-resistant fasteners for added protection. Furthermore, ensure proper ventilation in these areas to mitigate moisture buildup.

Floor Covering Considerations: Tailoring the Pattern to the Top Layer

The type of floor covering you intend to install directly impacts the ideal fastener pattern. Different materials have varying degrees of flexibility, thickness, and sensitivity to imperfections in the subfloor.

Thin and rigid materials, such as ceramic tile or laminate, are particularly unforgiving. They require a perfectly flat and stable underlayment to prevent cracking, lippage (uneven tile edges), or telegraphing of imperfections. In these cases, a tighter fastener pattern is crucial to minimize any potential movement or deflection in the OSB.

More flexible materials, such as vinyl or carpet, can tolerate minor imperfections. However, even with these forgiving options, a solid and secure underlayment is essential for long-term performance and preventing issues like buckling or uneven wear.

Always consult the flooring manufacturer’s recommendations for subfloor preparation, as they may specify particular fastener pattern requirements.

Subfloor Condition: Addressing Underlying Issues

The condition of the existing subfloor plays a significant role in determining the appropriate fastener pattern. An uneven, damaged, or weak subfloor can compromise the effectiveness of the fastener pattern and lead to premature failure.

If the subfloor is uneven, shimming may be necessary to create a level surface before installing the OSB underlayment. A self-leveling compound can also be used for more extensive leveling.

If the subfloor is damaged or weak, it may need to be repaired or reinforced before proceeding. This could involve replacing damaged sections, adding additional support, or applying a reinforcing membrane.

Regardless of the subfloor’s condition, it’s crucial to ensure that it is clean, dry, and free of debris before installing the OSB underlayment. Addressing these underlying issues will create a solid foundation for your new floor and ensure the long-term success of your installation.

Floor covering considerations add another layer of complexity to fastener pattern selection. Different materials react differently to the underlying structure. A rigid material like tile, for example, demands a more stable and uniform subfloor than a flexible material like carpet.

Step-by-Step: Proper Installation Techniques for OSB Underlayment

The devil is in the details, as they say, and when it comes to OSB underlayment installation, adherence to proven techniques is paramount. A haphazard approach, even with the correct fastener pattern in mind, can lead to the same problems you’re trying to avoid. This section breaks down the installation process into manageable steps, ensuring a solid foundation for your finished floor.

Preparing the Subfloor: The Foundation of Success

Subfloor preparation is arguably the most critical step in the entire process. A clean, level, and structurally sound subfloor is essential for optimal OSB underlayment performance. Neglecting this step is akin to building a house on sand.

First, thoroughly inspect the existing subfloor for any signs of damage, such as rot, water stains, or loose boards. Repair or replace any damaged sections before proceeding.

Next, clean the subfloor meticulously. Remove all debris, dirt, dust, and old adhesive residue. A shop vacuum works wonders for this task.

Finally, ensure the subfloor is level. Use a long straightedge and level to identify any high or low spots. Minor imperfections can often be feathered out with leveling compound. For more significant unevenness, consider sanding down high spots or adding shims to low areas.

Adhesive Application: When and How?

The use of adhesive in conjunction with fasteners is a subject of debate and often depends on the specific application and manufacturer recommendations. In general, adhesive provides an added layer of security, minimizing movement and reducing the likelihood of squeaks.

If adhesive is recommended, choose a high-quality construction adhesive that is specifically designed for wood-to-wood bonding. Apply the adhesive in a serpentine pattern to the back of the OSB sheet, ensuring full coverage. Avoid applying excessive amounts, as this can create a mess and potentially interfere with fastener placement.

Work in manageable sections, applying adhesive to only one or two sheets at a time to prevent it from drying out before the OSB is properly secured.

Mastering Fastener Placement: Precision is Key

With the subfloor prepped and adhesive applied (if applicable), it’s time to focus on fastener placement. This is where precision and attention to detail truly matter.

Always adhere to the recommended fastener pattern for your specific OSB thickness and application. Use a measuring tape and pencil to mark the fastener locations on the OSB sheet before installation.

When using a nail gun or screw gun, adjust the depth setting to ensure that the fasteners are driven flush with the surface of the OSB, without over-driving them. Over-driving fasteners can damage the OSB and reduce their holding power.

Maintain a consistent and even spacing between fasteners, paying close attention to edge distance requirements. Avoid placing fasteners too close to the edge of the OSB, as this can cause splitting and weaken the connection.

For best results, use a consistent, firm pressure when driving each fastener. This ensures a uniform and secure connection between the OSB and the subfloor.

Alignment and Gap Management: A Seamless Foundation

Proper alignment and gap management are crucial for creating a smooth and level surface for your finished floor covering.

When installing OSB sheets, ensure that they are properly aligned with each other, leaving a small expansion gap (typically 1/8 inch) between each sheet. This allows for expansion and contraction due to changes in humidity and temperature.

Use shims or spacers to maintain the correct gap while securing the OSB with fasteners. This ensures a consistent and uniform expansion joint throughout the floor.

Stagger the seams of the OSB sheets to avoid creating continuous lines of weakness. This distributes the load more evenly and enhances the overall strength and stability of the subfloor.

After installation, inspect the entire surface for any gaps or unevenness. Fill any gaps with wood filler or shims, and sand down any high spots to create a perfectly smooth and level surface.

Floor covering considerations add another layer of complexity to fastener pattern selection. Different materials react differently to the underlying structure. A rigid material like tile, for example, demands a more stable and uniform subfloor than a flexible material like carpet.

The devil is in the details, as they say, and when it comes to OSB underlayment installation, adherence to proven techniques is paramount. A haphazard approach, even with the correct fastener pattern in mind, can lead to the same problems you’re trying to avoid. This section breaks down the installation process into manageable steps, ensuring a solid foundation for your finished floor.

Playing by the Rules: Building Codes and Manufacturer Guidelines

Installing OSB underlayment isn’t just about following general best practices; it’s also about adhering to specific regulations and recommendations. Ignoring these guidelines can lead to failed inspections, costly rework, and, more importantly, compromised structural integrity and safety. This section emphasizes the critical role of building codes and manufacturer specifications in ensuring a compliant and successful installation.

The Imperative of Consulting Building Codes

Local building codes are the law of the land when it comes to construction. They are designed to ensure the safety and structural integrity of buildings, and they often specify minimum requirements for OSB underlayment installation, including fastener patterns.

These codes can vary significantly depending on your location, so it’s crucial to consult the relevant authorities before beginning any work. Don’t assume that what worked in one jurisdiction will be acceptable in another.

Failure to comply with building codes can result in a failed inspection, which can lead to delays, fines, and the need to redo the work.

Worse, non-compliance can create safety hazards and structural weaknesses that could have serious consequences down the line.

Deciphering Manufacturer Specifications

In addition to building codes, you must also pay close attention to the manufacturer’s specifications for both the OSB underlayment and the fasteners you are using.

These specifications provide valuable information about the proper installation techniques, including recommended fastener patterns, fastener types, and edge distances.

Manufacturer specifications are not just suggestions; they are based on rigorous testing and engineering analysis.

Deviating from these specifications can void warranties and compromise the performance of the materials.

Where to Find Manufacturer Specifications

Manufacturer specifications are typically available on the product packaging, on the manufacturer’s website, or by contacting the manufacturer directly. Look for technical data sheets, installation guides, and warranty information. Pay close attention to any specific instructions related to fastener patterns and installation techniques.

Understanding the Fine Print

Manufacturer specifications can sometimes be technical and difficult to understand. If you’re unsure about any aspect of the specifications, don’t hesitate to contact the manufacturer for clarification. It’s better to ask questions upfront than to make mistakes that could compromise the installation.

The Role of Inspections

Building inspections are an essential part of the construction process. They are designed to ensure that work is being done in accordance with building codes and manufacturer specifications.

During an inspection, a building inspector will examine the OSB underlayment installation to verify that the correct fastener pattern is being used, that the fasteners are properly installed, and that the overall installation meets all applicable requirements.

If the installation fails inspection, the inspector will issue a notice of violation, which will outline the steps that need to be taken to correct the deficiencies.

Failing to address these deficiencies can lead to further delays, fines, and legal action.

Therefore, it’s essential to be prepared for inspections by carefully following all applicable building codes and manufacturer specifications.

OSB Underlayment Fastener Pattern: Common Questions

This FAQ addresses frequently asked questions regarding the proper fastening of OSB underlayment. We aim to clarify common mistakes and ensure a successful flooring installation.

What is the recommended fastener pattern for OSB underlayment?

The typical recommendation for an OSB underlayment fastener pattern is every 6 inches along the edges and every 8 inches in the field. This ensures proper support and minimizes movement that can lead to squeaks or uneven flooring.

Why is the fastener pattern so important for OSB underlayment?

An incorrect osb underlayment fastener pattern can result in loose boards, nail pops, and ultimately, flooring failure. Insufficient fasteners can cause the underlayment to flex, leading to wear and tear on the finished floor.

What type of fasteners should I use for OSB underlayment?

Use ring-shank nails or screws specifically designed for underlayment. These fasteners provide better holding power than standard nails and are less likely to loosen over time. Ensure the fastener length is appropriate for the combined thickness of the subfloor and OSB underlayment.

What happens if I over-fasten the OSB underlayment?

Over-fastening can be just as problematic as under-fastening. Too many fasteners can damage the OSB underlayment, weaken its structure, and even cause it to buckle. Adhering to the recommended osb underlayment fastener pattern is crucial.

So, be sure to double-check that osb underlayment fastener pattern before you lay down that flooring! A little attention to detail here can save you a world of headaches (and squeaks!) later. Happy flooring!