Fourier Transform Infrared Spectroscopy (FTIR), a powerful analytical technique, plays a crucial role in polystyrene ir spectrum analysis. Polymer science, the field dedicated to understanding macromolecules, benefits greatly from the detailed molecular information provided by FTIR. Specifically, the analysis of polystyrene using IR spectroscopy often involves comparing the obtained spectrum to established databases like those maintained by the NIST (National Institute of Standards and Technology). Researchers at institutions like the Fraunhofer Institute frequently utilize polystyrene ir spectrum analysis to characterize material properties and ensure quality control. Understanding the nuances of polystyrene ir spectrum analysis is key to unlocking a deeper understanding of this widely used material.

Polystyrene, a ubiquitous synthetic polymer, plays a crucial role in countless aspects of modern life. From protective packaging and disposable cutlery to insulation materials and laboratory ware, its versatility and cost-effectiveness have made it a staple in numerous industries. Understanding the properties and composition of polystyrene is therefore paramount for ensuring product quality, optimizing performance, and exploring new applications.

The Role of Infrared Spectroscopy

Among the arsenal of analytical techniques available to scientists and engineers, Infrared (IR) spectroscopy stands out as a powerful and non-destructive method for characterizing polymers like polystyrene.

IR spectroscopy probes the vibrational modes of molecules, providing a unique fingerprint that reflects their structural arrangement and chemical composition.

IR Spectrum Analysis: A Window into Molecular Structure

By analyzing the IR spectrum of a polystyrene sample, we can gain invaluable insights into its molecular structure, including the presence of specific functional groups, the degree of polymerization, and the presence of any additives or contaminants.

This information is essential for quality control, material identification, and understanding the behavior of polystyrene under different conditions. This exploration into the world of polystyrene and IR spectroscopy will uncover the secrets held within its spectral data.

Among the arsenal of analytical techniques available to scientists and engineers, Infrared (IR) spectroscopy stands out as a powerful and non-destructive method for characterizing polymers like polystyrene. IR spectroscopy probes the vibrational modes of molecules, providing a unique fingerprint that reflects their structural arrangement and chemical composition. By analyzing the IR spectrum of a polystyrene sample, we can gain invaluable insights into its molecular structure, including the presence of specific functional groups, the degree of polymerization, and the presence of any additives or contaminants. This information is essential for quality control, material identification, and understanding the behavior of polystyrene under different conditions. This exploration into the world of polystyrene and IR spectroscopy will uncover the secrets held within its spectral data. Before we can dissect the nuances of a polystyrene IR spectrum, however, it’s crucial to understand the fundamental principles that underpin this powerful analytical technique.

The Fundamentals of Infrared Spectroscopy

At its core, Infrared (IR) spectroscopy leverages the interaction between infrared radiation and the vibrational modes of molecules to glean information about their structure and composition. This technique hinges on the principle that molecules absorb specific frequencies of IR radiation, causing them to vibrate in distinct ways. By analyzing the pattern of absorption, we can identify the functional groups present in the molecule and, consequently, deduce its structure.

The Interaction of Molecules with Infrared Radiation

Molecules are not static entities; their atoms are constantly in motion, vibrating around their equilibrium positions. These vibrations can be categorized into different modes, such as stretching (changes in bond length) and bending (changes in bond angle).

When a molecule is exposed to infrared radiation, it will only absorb radiation that matches the frequency of one of its vibrational modes. This absorption of energy causes the amplitude of the vibration to increase.

The frequencies at which a molecule absorbs infrared radiation are determined by the masses of the atoms involved in the vibration, the strength of the bonds between them, and the overall molecular structure.

Key Spectroscopic Terms: Wavenumber, Transmittance, and Absorbance

To interpret an IR spectrum effectively, it’s essential to understand the meaning of several key terms:

-

Wavenumber (cm-1): This is the reciprocal of the wavelength and is typically used to represent the position of peaks in an IR spectrum. It is directly proportional to the frequency of vibration and, therefore, the energy of the absorbed radiation. Higher wavenumbers correspond to higher energy vibrations.

-

Transmittance (%T): This refers to the fraction of incident infrared radiation that passes through the sample and reaches the detector. A high transmittance value indicates that the sample absorbs little radiation at that particular wavenumber, while a low transmittance value indicates strong absorption.

-

Absorbance (A): Absorbance is the logarithmic measure of the amount of light absorbed by the sample. It is inversely proportional to transmittance (A = -log T). In IR spectra, absorbance is often used to quantify the amount of a specific component in a sample.

An IR spectrum is essentially a plot of either transmittance or absorbance as a function of wavenumber. The peaks in the spectrum correspond to the frequencies at which the molecule absorbs infrared radiation, and their positions and intensities provide information about the molecule’s structure and concentration.

Molecular Vibrations and Absorption Bands

The relationship between molecular vibrations and absorption bands is the cornerstone of IR spectroscopy. Each vibrational mode of a molecule gives rise to a specific absorption band in the IR spectrum.

Different functional groups (e.g., C=O, O-H, N-H) have characteristic vibrational frequencies and, therefore, give rise to absorption bands in specific regions of the IR spectrum.

For example, a carbonyl group (C=O) typically exhibits a strong absorption band in the region of 1700-1750 cm-1, while an O-H group typically exhibits a broad absorption band in the region of 3200-3600 cm-1.

By identifying the positions of these absorption bands, we can determine the presence of specific functional groups in the molecule and, consequently, deduce its structure. The intensity of the absorption band is related to the amount of the functional group present in the sample. Stronger absorption bands indicate a higher concentration of the corresponding functional group.

The shape of an absorption band can also provide valuable information. Broad bands, for example, may indicate the presence of hydrogen bonding or other intermolecular interactions.

Among the arsenal of analytical techniques available to scientists and engineers, Infrared (IR) spectroscopy stands out as a powerful and non-destructive method for characterizing polymers like polystyrene. IR spectroscopy probes the vibrational modes of molecules, providing a unique fingerprint that reflects their structural arrangement and chemical composition. By analyzing the IR spectrum of a polystyrene sample, we can gain invaluable insights into its molecular structure, including the presence of specific functional groups, the degree of polymerization, and the presence of any additives or contaminants. This information is essential for quality control, material identification, and understanding the behavior of polystyrene under different conditions. This exploration into the world of polystyrene and IR spectroscopy will uncover the secrets held within its spectral data. Before we can dissect the nuances of a polystyrene IR spectrum, however, it’s crucial to understand the fundamental principles that underpin this powerful analytical technique.

With a solid foundation in the basics of IR spectroscopy, we are now equipped to delve into the heart of our analysis: the polystyrene IR spectrum itself. Let’s embark on a journey to decode the intricate landscape of peaks and valleys that constitute the spectral fingerprint of this ubiquitous polymer.

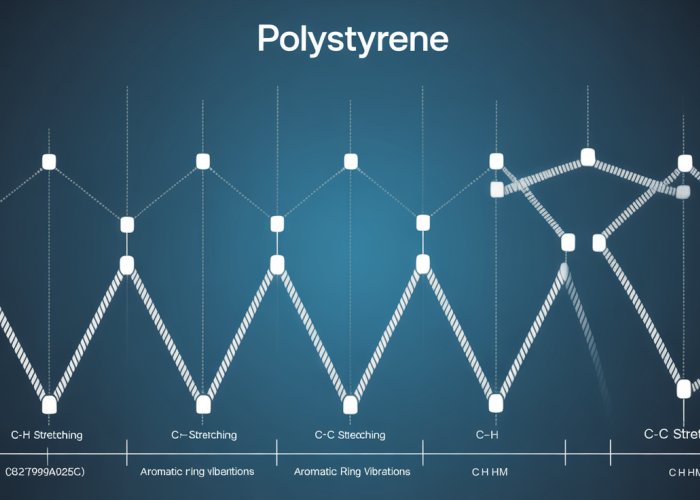

Decoding the Polystyrene IR Spectrum: A Comprehensive Guide

The IR spectrum of polystyrene is a rich tapestry of absorption bands, each corresponding to specific vibrational modes within the molecule. By carefully analyzing the positions and intensities of these peaks, we can gain a wealth of information about the polymer’s structure and composition. This section serves as a detailed guide, illuminating the prominent peaks associated with the key functional groups present in polystyrene.

Key Functional Groups and Their Characteristic Peaks

Polystyrene’s structure is characterized by the presence of aromatic rings, carbon-hydrogen (C-H) bonds, and carbon-carbon (C-C) bonds. Each of these functional groups gives rise to distinct peaks in the IR spectrum, allowing for their identification and characterization.

Aromatic Rings

The aromatic ring is a defining feature of polystyrene, and its presence is readily apparent in the IR spectrum. Several characteristic peaks arise from the vibrational modes of the aromatic ring, providing valuable diagnostic information.

-

3000-3100 cm-1: Sharp, weak to medium intensity peaks in this region correspond to the aromatic C-H stretching vibrations. These peaks are typically sharper and occur at slightly higher wavenumbers compared to aliphatic C-H stretches.

-

1600 cm-1 and 1585 cm-1: These peaks are attributed to the in-plane ring stretching vibrations of the aromatic ring. They are usually strong and easily identifiable.

-

1495 cm-1: Another peak associated with aromatic ring vibrations, often of medium intensity.

-

699 cm-1 and 756 cm-1: These strong peaks correspond to out-of-plane C-H bending vibrations of the monosubstituted benzene ring. The position and relative intensity of these peaks are highly characteristic of polystyrene.

Carbon-Hydrogen Bonds (C-H Bonds)

Polystyrene contains both aliphatic (backbone) and aromatic C-H bonds. These bonds give rise to distinct stretching and bending vibrations in the IR spectrum.

-

2850-3000 cm-1: A series of peaks in this region corresponds to aliphatic C-H stretching vibrations. These peaks are typically broader and less intense than the aromatic C-H stretches.

-

1450 cm-1: This peak is associated with aliphatic C-H bending vibrations (scissoring mode).

-

~906 cm-1, ~960 cm-1: Peaks related to C-H out-of-plane bending

Carbon-Carbon Bonds (C-C Bonds)

The carbon-carbon bonds within the polystyrene backbone also contribute to the IR spectrum.

-

1600 cm-1: The in-plane ring stretching vibrations are attributed to C=C bonds of the aromatic ring.

-

1452 cm-1: C-C stretching band in the polymer backbone, showing its presence in the compound.

Peak Identification and Spectral Interpretation

Interpreting a polystyrene IR spectrum involves carefully identifying the major peaks and correlating them with the corresponding functional groups. Here’s a step-by-step guide:

-

Identify the Baseline: Ensure the baseline is properly corrected before interpreting the spectrum.

-

Locate Prominent Peaks: Begin by identifying the most intense peaks in the spectrum, particularly those associated with the aromatic ring (3000-3100 cm-1, 1600 cm-1, 1585 cm-1, 699 cm-1 and 756 cm-1).

-

Assign Functional Groups: Assign each peak to its corresponding functional group based on its position and intensity. Consult reference tables and spectral databases for assistance.

-

Analyze Peak Shapes and Intensities: Pay attention to the shapes and intensities of the peaks. Broad peaks may indicate the presence of hydrogen bonding or amorphous regions, while sharp peaks suggest crystalline regions. Variations in peak intensities can reflect changes in the concentration of specific functional groups.

-

Consider Sample History: Variations in peak positions and intensities can reveal information about the polystyrene sample, such as its degree of polymerization, tacticity, or the presence of additives. For instance, oxidation can introduce carbonyl groups (C=O), which will appear as a new peak around 1720 cm-1.

By meticulously following these steps, one can effectively decode the polystyrene IR spectrum and extract valuable insights into the polymer’s structure, composition, and properties.

Decoding the intricacies of the polystyrene IR spectrum provides a powerful tool for understanding its molecular makeup. However, obtaining a high-quality, reliable spectrum is paramount. The accuracy and interpretability of the results hinge not only on theoretical understanding but also on meticulous experimental technique.

Ensuring Accurate Analysis: Practical Considerations and Techniques

The journey from sample to spectrum is paved with practical considerations that can significantly impact the quality of the data. This section delves into the essential techniques and methodologies required to obtain reliable and meaningful IR spectra of polystyrene, focusing on sample preparation, the advantages of FTIR spectroscopy, the utility of ATR sampling, and the critical role of data processing.

Sample Preparation Techniques

Proper sample preparation is the cornerstone of accurate IR spectroscopy. The method chosen depends on the physical form of the polystyrene sample, be it a solid, film, or solution.

For solid samples, one common technique involves grinding the polystyrene into a fine powder and dispersing it in a non-absorbing matrix like potassium bromide (KBr). This mixture is then pressed into a transparent pellet, which is suitable for IR analysis.

Alternatively, polystyrene can be dissolved in a suitable solvent, and a thin film can be cast onto an IR-transparent window. Care must be taken to select a solvent that does not interfere with the polystyrene spectrum.

For polystyrene films, direct analysis is possible, but the film thickness needs careful control to avoid saturation effects, where strong absorption bands become flattened and lose their quantitative information.

The importance of proper sample preparation cannot be overstated. Contamination, uneven dispersion, or inappropriate film thickness can all lead to inaccurate or misleading results.

Fourier Transform Infrared Spectroscopy (FTIR) and its Advantages

Fourier Transform Infrared Spectroscopy (FTIR) has become the workhorse of modern IR spectroscopy. It has largely replaced traditional dispersive IR spectrometers due to its superior speed, sensitivity, and accuracy.

In FTIR, the sample is illuminated with an infrared beam that contains all frequencies simultaneously. The resulting interferogram is then mathematically transformed into a spectrum using Fourier transformation.

This approach offers several key advantages:

- Improved Signal-to-Noise Ratio: FTIR instruments acquire data over the entire spectral range simultaneously, leading to a significant improvement in the signal-to-noise ratio compared to dispersive instruments.

- Higher Resolution: FTIR spectrometers typically offer higher spectral resolution, allowing for the separation of closely spaced peaks and more detailed spectral analysis.

- Faster Acquisition Times: The simultaneous measurement of all frequencies allows for rapid data acquisition, making FTIR well-suited for analyzing dynamic processes or high-throughput screening.

These advantages make FTIR the preferred method for most polystyrene IR spectroscopy applications.

Attenuated Total Reflectance (ATR)

Attenuated Total Reflectance (ATR) is a powerful sampling technique, especially well-suited for solid samples like polystyrene. It simplifies sample preparation and minimizes the need for sample manipulation.

In ATR, the infrared beam is directed onto a crystal with a high refractive index. The beam undergoes total internal reflection within the crystal, creating an evanescent wave that penetrates a short distance into the sample in contact with the crystal.

The sample absorbs some of the evanescent wave, and the attenuated beam is then detected. The resulting spectrum is representative of the sample’s surface.

ATR offers several key benefits:

- Minimal Sample Preparation: Solid samples can often be analyzed directly without grinding or dissolving.

- Non-Destructive: ATR is a non-destructive technique, allowing for further analysis of the sample after IR spectroscopy.

- Suitable for Opaque Samples: ATR can be used to analyze samples that are too thick or opaque for transmission measurements.

ATR is particularly useful for analyzing polystyrene films, coatings, and other solid forms, where traditional transmission methods may be challenging.

Data Processing: Baseline Correction

Even with careful sample preparation and optimal instrumentation, IR spectra often exhibit baseline distortions due to scattering effects or instrument imperfections. These distortions can interfere with accurate peak identification and quantification.

Baseline correction is a crucial data processing step that removes these distortions and ensures a flat, level baseline across the spectrum.

This is typically achieved by mathematically fitting a baseline curve to the spectrum and subtracting it from the data. Several algorithms are available for baseline correction, and the choice of algorithm depends on the nature of the baseline distortion.

Proper baseline correction is essential for obtaining accurate and reliable IR spectra of polystyrene, enabling precise peak analysis and meaningful interpretation of the data.

Decoding the intricacies of the polystyrene IR spectrum provides a powerful tool for understanding its molecular makeup. However, obtaining a high-quality, reliable spectrum is paramount. The accuracy and interpretability of the results hinge not only on theoretical understanding but also on meticulous experimental technique.

But the power of polystyrene IR spectrum analysis extends far beyond the laboratory. Its applications are incredibly diverse and vital in numerous real-world scenarios. Let’s explore how this analytical technique is deployed in various sectors, from ensuring product quality to advancing materials science.

Real-World Applications of Polystyrene IR Spectrum Analysis

Infrared (IR) spectroscopy isn’t just a theoretical exercise; it’s a practical tool with diverse applications in the real world. The ability to quickly and accurately analyze the composition and structure of polystyrene makes it invaluable across various industries. Here’s a look at some of the key areas where polystyrene IR spectrum analysis plays a critical role.

Quality Control: Maintaining Standards in Polystyrene Production

In the manufacturing of polystyrene, consistency is key. IR spectroscopy serves as a powerful quality control tool, ensuring that each batch of polystyrene meets the required specifications.

By comparing the IR spectrum of a sample against a reference spectrum of known, acceptable material, manufacturers can quickly identify any deviations in the chemical composition or structure.

This allows for immediate corrective action, preventing substandard material from reaching the market.

This method is particularly useful for detecting impurities, variations in polymer chain length, or the presence of unwanted additives. Regular IR spectrum analysis guarantees that the final product adheres to pre-defined standards, crucial for applications where performance and reliability are paramount.

Material Identification: Confirming Polystyrene Identity

With a wide array of polymers available, accurately identifying a material is essential in various applications. IR spectroscopy offers a rapid and reliable method for verifying the identity of polystyrene samples.

Every polymer possesses a unique IR spectrum, acting as a fingerprint that distinguishes it from others.

By comparing the spectrum of an unknown sample to a database of known polymer spectra, it can be confirmed whether the material is indeed polystyrene, and even which specific type of polystyrene it is.

This is particularly useful in recycling processes, where accurate sorting of plastics is crucial for efficient and effective recycling. It is also important in forensic analysis, reverse engineering, and situations where material traceability is needed.

Degradation Studies: Understanding Environmental Impact

Polystyrene, like all polymers, is susceptible to degradation over time due to environmental factors such as UV radiation, heat, and oxidation. IR spectroscopy plays a crucial role in monitoring these degradation processes.

As polystyrene degrades, its chemical structure changes, which is reflected in its IR spectrum.

By tracking changes in the intensity and position of specific peaks, researchers can quantify the extent of degradation and understand the mechanisms involved.

This information is invaluable for developing strategies to improve the durability of polystyrene products, such as adding stabilizers or modifying the polymer structure to enhance resistance to environmental degradation.

It’s also critical for assessing the long-term environmental impact of polystyrene waste and developing more sustainable disposal methods.

Polymer Blends: Analyzing Composition and Compatibility

Polystyrene is often blended with other polymers to achieve specific properties, such as improved impact resistance or thermal stability. IR spectroscopy is a valuable tool for analyzing the composition of these polymer blends.

The IR spectrum of a polymer blend will typically exhibit peaks corresponding to each of the individual polymers present.

By carefully analyzing the relative intensities of these peaks, researchers can determine the relative proportions of each polymer in the blend.

Furthermore, IR spectroscopy can provide information about the compatibility of the different polymers. Changes in peak shape or position can indicate interactions between the polymers, which can affect the overall properties of the blend.

This information is crucial for optimizing the formulation of polymer blends to achieve the desired performance characteristics.

FAQs: Polystyrene IR Spectrum Analysis

Here are some frequently asked questions about polystyrene IR spectrum analysis to help you better understand the guide.

What makes a polystyrene IR spectrum unique?

Polystyrene’s IR spectrum exhibits characteristic peaks arising from its phenyl ring vibrations and aliphatic C-H stretches. Specific peaks at approximately 3060, 3028, 1601, 1493, and 700 cm⁻¹ are commonly used to identify polystyrene. These peaks allow for definitive polystyrene ir spectrum analysis.

What factors can affect the polystyrene IR spectrum?

The exact appearance of a polystyrene IR spectrum can be influenced by several factors. These include the sample preparation method, the presence of additives or impurities, and the grade of polystyrene used. Proper sample preparation is key for accurate polystyrene ir spectrum analysis.

How can I differentiate polystyrene from similar polymers using IR?

While other polymers may have similar functional groups, the specific combination and intensities of the peaks in the polystyrene IR spectrum are unique. Careful analysis of peak positions and ratios allows for its differentiation from polymers like polyethylene or polypropylene. Detailed examination is necessary for conclusive polystyrene ir spectrum analysis.

What are some common applications of polystyrene IR spectrum analysis?

Polystyrene IR spectrum analysis is used in quality control to confirm the identity of polystyrene materials. It is also employed in research and development to study the effects of modifications or degradation on the polymer structure. Therefore, it is helpful in a variety of industrial applications where the nature of the polymer needs verification.

And that’s a wrap on polystyrene ir spectrum analysis! Hope this guide helped you decode those squiggly lines and understand your samples a little better. Now go forth and spectroscopize!