Achieving precise measurements is crucial in fields ranging from pharmaceutical research to environmental monitoring. A fundamental technique enabling this accuracy is standard curve quantitative analysis, particularly vital when working with tools like the ELISA reader in a laboratory setting. The National Institute of Standards and Technology (NIST) sets the benchmarks for these methodologies, validating the reliability and reproducibility of resulting data. The goal of this approach is to quantify unknown samples by comparing them against a series of known concentrations using a standard curve quantitative methodology.

Quantitative analysis stands as a cornerstone of scientific inquiry, providing the means to measure the amount of a specific substance—the analyte—within a sample. This capability is indispensable across a spectrum of disciplines, from ensuring the safety and efficacy of pharmaceuticals to monitoring environmental pollutants and optimizing food production processes.

The accuracy and reliability of quantitative analysis are not merely academic concerns; they directly impact decision-making in critical areas such as healthcare, environmental protection, and industrial quality control.

At the heart of achieving trustworthy quantitative results lies the standard curve, a powerful tool that allows scientists to establish a relationship between the measured signal and the concentration of the analyte.

The Significance of Quantitative Analysis

Quantitative analysis plays a pivotal role in numerous scientific and industrial sectors.

In the pharmaceutical industry, it is essential for determining drug dosages, monitoring drug stability, and ensuring the consistency of drug formulations. Environmental scientists rely on quantitative analysis to measure the levels of pollutants in water, soil, and air, informing regulatory decisions and remediation efforts.

The food industry utilizes quantitative analysis to assess the nutritional content of food products, detect contaminants, and ensure compliance with food safety regulations.

These are just a few examples illustrating the broad applicability and vital importance of quantitative analysis in safeguarding public health, protecting the environment, and driving innovation across various sectors.

The Central Role of the Standard Curve

The standard curve serves as a calibration tool, enabling scientists to translate measured signals into meaningful concentration values.

By plotting the known concentrations of a series of standards against their corresponding instrument responses (e.g., absorbance, fluorescence), a standard curve is generated. This curve then serves as a reference for determining the concentration of an unknown sample by comparing its measured signal to the curve.

The accuracy of the standard curve directly impacts the reliability of the quantitative analysis.

A poorly constructed or improperly validated standard curve can lead to significant errors in concentration measurements, compromising the integrity of the entire analysis. Therefore, a thorough understanding of standard curve principles and best practices is essential for obtaining accurate and reliable quantitative results.

Overview of Key Topics

This article will delve into the fundamental principles of standard curves, providing a step-by-step guide to constructing robust and reliable curves.

We will explore the critical aspects of selecting appropriate standards, preparing serial dilutions, accurately measuring instrument responses, and employing statistical methods to evaluate curve performance.

Furthermore, the discussion will encompass best practices for using standard curves to determine the concentration of unknown samples, highlighting potential pitfalls and strategies for ensuring data accuracy.

Finally, real-world examples from various scientific fields will illustrate the practical applications of standard curve quantitative analysis and its impact on research and development. By mastering the principles and techniques outlined in this article, readers will be equipped to unlock the full potential of standard curves and achieve accurate, reliable, and reproducible quantitative results in their own work.

Quantitative analysis plays a pivotal role in numerous scientific and industrial sectors.

In the pharmaceutical industry, it is essential for determining drug dosages, monitoring drug stability, and ensuring the consistency of drug formulations. Environmental scientists rely on quantitative analysis to measure the levels of pollutants in water, soil, and air, informing regulatory decisions and remediation efforts.

The food industry utilizes quantitative analysis to assess the nutritional content of food products, detect contaminants, and ensure compliance with food safety regulations.

These are just a few examples illustrating the broad applicability and vital importance of quantitative analysis in safeguarding public health, protecting the environment, and driving innovation across various sectors.

The standard curve serves as a calibration tool, enabling scientists to translate measured signals into meaningful concentration values. It’s a bridge that connects the abstract world of instrument readings to the concrete reality of how much analyte is present.

Fundamentals: Demystifying the Standard Curve

At its core, a standard curve is a graphical representation that plots known concentrations of an analyte against their corresponding measured signals.

These signals can take various forms, such as absorbance, fluorescence, or electrochemical current, depending on the analytical technique employed.

Defining the Standard Curve

More specifically, the standard curve is a calibration curve which functions as a visual method for quantitative analysis.

It is created by analyzing samples with known properties and then used to measure samples with unknown properties.

The purpose of a standard curve is to establish a reliable relationship between the signal and the concentration, enabling scientists to determine the concentration of an unknown sample by comparing its signal to the curve.

This curve acts as a reference point, providing a means to translate instrument readings into meaningful concentration values. Without it, analytical measurements would be largely meaningless in a quantitative context.

The Relationship Between Concentration and Absorbance

The foundation of many standard curves, particularly those used in spectrophotometry, rests on the relationship between concentration and absorbance.

Absorbance is a measure of how much light a substance absorbs at a particular wavelength.

As the concentration of the analyte increases, the amount of light absorbed also increases proportionally, this correlation is key to making concentration determinations.

This direct relationship is not always linear across all concentrations. Therefore, selecting an appropriate concentration range and understanding the limitations of the assay are crucial for accurate quantitative analysis.

Exploring the Beer-Lambert Law

The Beer-Lambert Law mathematically describes the relationship between absorbance, concentration, and path length of the light beam through the sample.

Expressed as A = εbc, where:

- A is the absorbance,

- ε is the molar absorptivity (a measure of how strongly a chemical species absorbs light at a given wavelength),

- b is the path length (the distance the light travels through the sample),

- c is the concentration of the analyte.

The Beer-Lambert Law provides the theoretical basis for generating and interpreting standard curves.

It dictates that absorbance is directly proportional to concentration when the path length and molar absorptivity are kept constant.

However, deviations from this law can occur at high concentrations or due to instrumental artifacts, emphasizing the importance of careful experimental design and quality control.

The purpose of a standard curve is to establish a reliable relationship between the signal and the concentration, enabling the determination of unknown sample concentrations with confidence. Now, armed with an understanding of the standard curve’s fundamental purpose, let’s delve into the practical steps required to construct one that yields reliable and accurate results.

Building a Robust Standard Curve: A Step-by-Step Guide

Constructing a high-quality standard curve is crucial for obtaining accurate quantitative results. The following steps outline the process, emphasizing key considerations at each stage.

Selecting Appropriate Standards

The choice of standards is paramount to the accuracy of your standard curve.

-

Standards should be of high purity and well-characterized.

A certified reference material (CRM) is often the best option, as its concentration and purity are traceable to a recognized standard.

-

Ensure the standard is stable under the conditions of your experiment.

Consider factors such as temperature, light, and solvent compatibility.

-

The standard should be relevant to the analyte you are measuring in your samples.

Ideally, it should be the same chemical species or a closely related compound.

Creating Serial Dilutions

Serial dilution is a stepwise dilution process used to create a range of concentrations from a stock standard solution.

Preparing the Stock Solution

Begin by preparing a stock solution of your standard at a known concentration.

- Use a calibrated balance and volumetric glassware to ensure accuracy.

- Dissolve the standard in a suitable solvent, taking care to ensure complete dissolution.

- Document the preparation process, including the weight of the standard, the volume of solvent used, and the resulting concentration.

Performing Serial Dilutions

- Starting with the stock solution, perform serial dilutions to create a series of standards with decreasing concentrations.

-

Use a consistent dilution factor (e.g., 1:2, 1:10) for each step.

This simplifies calculations and minimizes errors.

- Change pipette tips between dilutions to prevent carryover.

- Thoroughly mix each dilution before proceeding to the next.

- Prepare enough volume of each standard to allow for multiple measurements.

-

Label each standard clearly with its concentration.

This avoids confusion during the measurement process.

Accurate Measurement of Absorbance

Accurate measurement of absorbance is essential for generating a reliable standard curve.

Instrument Calibration

Before making any measurements, calibrate your spectrophotometer according to the manufacturer’s instructions.

- This typically involves running a blank (a solution containing only the solvent) to zero the instrument.

- Use calibrated cuvettes or sample holders.

- Check the instrument’s performance using known standards or filters.

Sample Handling

- Ensure that your standards are at the same temperature as your instrument.

-

Wipe the outside of the cuvettes with a lint-free cloth before placing them in the instrument.

This removes any fingerprints or smudges that could interfere with the measurement.

-

Take multiple readings of each standard and calculate the average absorbance.

This reduces the impact of random errors.

Importance of Replicates

Replicates are multiple measurements of the same sample.

- Using replicates at each concentration level is crucial for improving the reliability of the standard curve.

- Replicates provide an estimate of the variability in your measurements.

- They allow you to identify and exclude outliers (measurements that are significantly different from the others).

-

The number of replicates you should use depends on the desired level of precision.

A minimum of three replicates is generally recommended.

- Calculate the average and standard deviation of the absorbance values for each concentration.

- Use these values to assess the precision of your measurements and to identify any potential problems with your standard curve.

The meticulous work involved in constructing a standard curve culminates in a crucial step: assessing its quality. A well-constructed standard curve is not merely a collection of data points; it’s a carefully calibrated tool that dictates the accuracy of your quantitative analysis. Therefore, rigorous evaluation is essential to ensure the curve meets the necessary criteria for reliable results. Let’s delve into the key aspects of this critical assessment.

Quality Assessment: Evaluating Your Standard Curve’s Performance

Once a standard curve is generated, it’s imperative to evaluate its quality to ensure it yields accurate and reliable results. This involves assessing linearity, performing regression analysis, interpreting the R-squared value, and determining the Limit of Detection (LOD) and Limit of Quantification (LOQ).

Assessing Linearity: Visual Inspection and Statistical Analysis

Linearity refers to the ability of a standard curve to produce results that are directly proportional to the concentration of the analyte within a specific range.

Visual Inspection

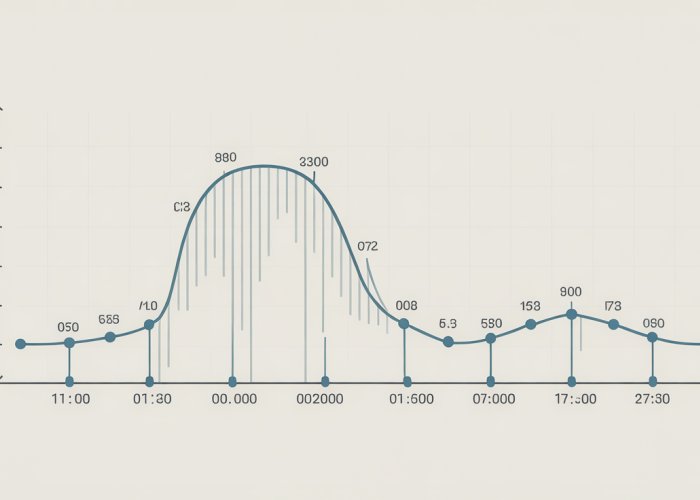

Begin by visually inspecting the standard curve plot. A linear standard curve should appear as a straight line across the range of concentrations tested. Look for any deviations from linearity, such as curves or plateaus, which may indicate issues with the assay or the standards used.

Statistical Analysis

While visual inspection is useful, it’s not sufficient for a thorough assessment of linearity. Statistical methods, such as calculating the residuals, are essential.

Residuals are the differences between the observed values and the values predicted by the regression line. If the standard curve is linear, the residuals should be randomly distributed around zero. A non-random pattern in the residuals, such as a funnel shape or a curve, indicates non-linearity.

Regression Analysis: Determining the Best-Fit Line

Regression analysis is a statistical technique used to determine the best-fit line for the standard curve data. The most common type of regression analysis used for standard curves is linear regression, which assumes a linear relationship between the concentration and the signal.

However, in some cases, a non-linear regression model may be more appropriate, especially if the standard curve exhibits significant non-linearity.

Linear Regression

Linear regression aims to find the line that minimizes the sum of the squared differences between the observed values and the values predicted by the line. The equation for a linear regression line is:

y = mx + b

Where:

- y is the signal (e.g., absorbance)

- x is the concentration

- m is the slope of the line

- b is the y-intercept

Non-Linear Regression

If the standard curve is non-linear, a non-linear regression model may be more appropriate. Several non-linear regression models are available, such as quadratic, exponential, and logarithmic models. The choice of model will depend on the shape of the standard curve.

Interpreting the R-Squared Value: Goodness of Fit

The R-squared value, also known as the coefficient of determination, is a statistical measure that indicates the proportion of the variance in the dependent variable (signal) that is predictable from the independent variable (concentration). In simpler terms, it tells you how well the regression line fits the data.

The R-squared value ranges from 0 to 1, with higher values indicating a better fit. An R-squared value of 1 indicates that the regression line perfectly fits the data, while an R-squared value of 0 indicates that the regression line does not fit the data at all.

As a general rule, an R-squared value of 0.99 or higher is considered acceptable for most standard curve applications. However, the acceptable R-squared value may vary depending on the specific application and the level of accuracy required.

Limit of Detection (LOD) and Limit of Quantification (LOQ): Assessing Sensitivity

The Limit of Detection (LOD) and Limit of Quantification (LOQ) are important parameters for assessing the sensitivity of an assay.

Limit of Detection (LOD)

The LOD is the lowest concentration of an analyte that can be reliably detected, but not necessarily quantified, by the assay. It is often defined as three times the standard deviation of the blank (or zero standard) divided by the slope of the standard curve:

LOD = 3

**(Standard Deviation of Blank) / Slope

Limit of Quantification (LOQ)

The LOQ is the lowest concentration of an analyte that can be reliably quantified with acceptable accuracy and precision. It is often defined as ten times the standard deviation of the blank divided by the slope of the standard curve:

LOQ = 10** (Standard Deviation of Blank) / Slope

The LOD and LOQ values are important for determining the range of concentrations that can be accurately measured by the assay. Samples with concentrations below the LOD should be reported as "not detected," while samples with concentrations between the LOD and LOQ should be interpreted with caution.

Ensuring Accuracy: Best Practices for Quantitative Analysis Using Standard Curves

With a validated standard curve in hand, the journey toward reliable quantitative analysis is far from over. The true power of the standard curve lies in its correct application and the implementation of rigorous quality control measures. It is imperative to understand the nuances of accuracy and precision and to proactively mitigate potential errors that can compromise results.

The Cornerstones: Accuracy and Precision

In quantitative analysis, accuracy refers to how close a measurement is to the true or accepted value, while precision reflects the reproducibility or repeatability of a measurement. Both are vital, yet distinct. A standard curve that is poorly constructed or improperly applied can negatively affect both accuracy and precision, leading to flawed conclusions.

For instance, if the standards used to generate the curve are not accurately prepared, or if the instrument used to measure absorbance is not properly calibrated, systematic errors will be introduced, resulting in inaccurate measurements. Similarly, inconsistent technique in sample preparation or measurement can lead to poor precision, even if the standard curve itself is accurate.

Navigating the Pitfalls: Common Errors in Standard Curve Generation

Several common pitfalls can undermine the integrity of a standard curve, leading to inaccurate quantitative results.

Dilution Errors

One of the most frequent sources of error is incorrect serial dilutions. A mistake in one dilution step will be propagated throughout the entire series, skewing the standard curve. It is crucial to use calibrated pipettes and to carefully verify each dilution step.

Measurement Inaccuracies

Inaccurate measurements, whether due to improperly calibrated instruments, air bubbles in the cuvette, or inconsistent reading times, can also compromise the standard curve. Regular instrument calibration is essential, as is careful attention to detail during the measurement process.

Standard Selection

The choice of standard is also critical. The standard should be chemically stable, of high purity, and appropriate for the analyte being measured. Using an inappropriate standard can lead to inaccurate results due to differences in the chemical properties or reactivity of the standard compared to the analyte in the unknown sample.

Decoding Unknowns: Determining Sample Concentration with Confidence

Once a reliable standard curve is established, it can be used to determine the concentration of an unknown sample. This process involves measuring the absorbance of the unknown sample and then interpolating its concentration from the standard curve.

Interpolation Techniques

Interpolation involves finding the concentration on the x-axis (concentration) that corresponds to the measured absorbance on the y-axis (absorbance). It is crucial to perform interpolation carefully to avoid errors. While manual interpolation is possible, it is generally more accurate to use software or statistical packages that can perform the calculation automatically.

Accounting for Error

It is also essential to consider the potential for error in the interpolation process. The standard curve is not perfect, and there will always be some uncertainty in the estimated concentration. This uncertainty can be quantified by calculating the confidence interval for the interpolated value. This provides a range within which the true concentration is likely to fall.

Upholding Data Integrity: The Role of Quality Control

Implementing robust quality control (QC) measures is essential for ensuring the reliability of results obtained using a standard curve. QC samples, with known concentrations, should be run alongside unknown samples to verify the accuracy of the standard curve and the entire analytical process.

If the measured concentrations of the QC samples deviate significantly from their known values, it indicates a problem with the standard curve or the analytical method. This requires immediate investigation and corrective action, such as re-running the standard curve or recalibrating the instrument.

In addition, it is good practice to regularly check the performance of the standard curve by analyzing control samples with known concentrations that span the range of the curve. This helps to ensure that the standard curve remains accurate and reliable over time.

Real-World Applications: Standard Curve Quantitative Analysis in Action

The principles and practices of standard curve quantitative analysis are not confined to textbooks and laboratories. They are the bedrock of countless real-world applications, impacting diverse fields and driving innovation across scientific disciplines.

Let’s examine how these techniques manifest in the pharmaceutical industry, environmental monitoring, and food science, showcasing their critical role in advancing knowledge and ensuring safety.

Pharmaceutical Industry: Ensuring Drug Quality and Efficacy

In the pharmaceutical realm, accuracy is paramount. The development, manufacturing, and quality control of drugs hinge on precise quantitative analysis. Standard curves play a vital role in several key areas:

-

Drug Discovery and Development: Standard curves are used to quantify the concentration of drug candidates in biological samples during preclinical and clinical trials.

This allows researchers to assess pharmacokinetics (how the body processes the drug) and pharmacodynamics (how the drug affects the body).

-

Quality Control: Standard curves are essential for determining the purity and potency of drug products.

Each batch of medication must meet stringent quality standards, and accurate quantitative analysis is crucial for ensuring that these standards are consistently met.

-

Bioavailability Studies: Standard curves help determine how much of a drug is absorbed into the bloodstream and reaches its target site.

This information is critical for optimizing drug formulations and dosages to maximize therapeutic efficacy.

The consequences of inaccurate quantitative analysis in the pharmaceutical industry can be dire, potentially leading to ineffective treatments or even harmful side effects. The rigor of standard curve methodology is, therefore, non-negotiable.

Environmental Monitoring: Safeguarding Our Ecosystems

Environmental monitoring relies heavily on quantitative analysis to assess the levels of pollutants and contaminants in air, water, and soil. Standard curves are indispensable tools for:

-

Water Quality Analysis: Determining the concentration of pollutants, such as heavy metals, pesticides, and industrial chemicals, in water sources.

This is essential for ensuring that water is safe for human consumption and for protecting aquatic ecosystems.

-

Air Quality Monitoring: Measuring the levels of air pollutants, such as particulate matter, nitrogen oxides, and sulfur dioxide.

This data is used to assess air quality, identify pollution sources, and implement strategies to improve air quality.

-

Soil Contamination Assessment: Quantifying the concentration of contaminants in soil, such as heavy metals and organic pollutants.

This helps to identify contaminated sites, assess the risk to human health and the environment, and develop remediation strategies.

By providing accurate and reliable measurements of environmental contaminants, standard curve quantitative analysis enables informed decision-making and effective environmental protection.

Food Science: Ensuring Food Safety and Quality

In the food industry, quantitative analysis is crucial for ensuring food safety, quality, and nutritional value. Standard curves are employed for:

-

Nutritional Analysis: Determining the levels of vitamins, minerals, and other nutrients in food products.

This information is essential for accurate labeling and for ensuring that consumers receive adequate nutrition.

-

Food Safety Testing: Detecting and quantifying the presence of contaminants, such as pesticides, mycotoxins, and bacterial toxins, in food products.

This is critical for preventing foodborne illnesses and ensuring that food is safe for consumption.

-

Quality Control: Monitoring the levels of key quality indicators, such as acidity, sugar content, and color, in food products.

This helps to maintain consistent product quality and meet consumer expectations.

The use of standard curves in food science helps protect public health by ensuring the safety and nutritional value of the food supply.

Impact on Research and Development

Beyond these specific industries, standard curve quantitative analysis has a profound impact on research and development across a wide range of scientific disciplines.

By enabling researchers to accurately quantify substances and processes, standard curves accelerate scientific discoveries in areas such as:

- Biotechnology: Developing new diagnostic tests and therapies.

- Materials Science: Characterizing the properties of new materials.

- Basic Research: Elucidating fundamental biological and chemical processes.

In essence, the accurate quantification made possible by standard curves fuels innovation and advances our understanding of the world around us. Without reliable quantitative data, scientific progress would be severely hampered.

FAQs: Understanding Standard Curve Quantitative Analysis

Here are some frequently asked questions about standard curve quantitative analysis to help you better understand the process.

What is a standard curve and why is it needed?

A standard curve is a graph that plots known concentrations of a substance against corresponding measurements (e.g., absorbance, fluorescence). It’s essential for standard curve quantitative analysis because it provides a reference to determine the unknown concentration of a sample by comparing its measurement to the curve.

What are the key components required to create a standard curve?

You need a series of standards with known, varying concentrations of the target substance. You also need an instrument that can accurately measure a signal related to the concentration (e.g., a spectrophotometer). Finally, software is often used to generate the curve and perform the standard curve quantitative analysis.

What factors can affect the accuracy of a standard curve quantitative analysis?

Several factors can impact accuracy, including inaccurate standards, instrument errors, matrix effects (interference from other components in the sample), and poor curve fitting. Proper standard preparation, regular instrument calibration, and careful sample preparation are crucial for accurate standard curve quantitative analysis.

How do I interpret the results obtained from a standard curve?

Once you’ve measured your unknown sample, locate its corresponding measurement on the standard curve. From that point, find the corresponding concentration on the x-axis (concentration axis). This concentration represents the estimated amount of your target substance in the sample, based on the standard curve quantitative approach.

Alright, that’s a wrap on standard curve quantitative! Hopefully, this gives you a solid handle on the basics and points you in the right direction. Go forth and analyze!