The design of a toothpick, often utilizing wood or bamboo, directly influences its functionality. Understanding the manufacturing process reveals the tolerances involved in creating these ubiquitous tools. Consequently, the diameter of a toothpick becomes a critical measurement, especially when considering industry standards established by organizations such as the FDA (Food and Drug Administration), which regulate materials that come into contact with food. Examining the diameter ensures that the toothpick performs its intended purpose—removing food debris—without posing a safety risk.

The Mighty Toothpick – More Than Meets the Eye

The humble toothpick, a slender sliver of wood or bamboo, is ubiquitous. It’s found in restaurants, homes, and even pockets, ready to dislodge that stray bit of food or serve as an impromptu crafting tool. Its simplicity belies a surprising depth, particularly when we consider a single, seemingly insignificant dimension: its diameter.

While most might consider all toothpicks created equal, understanding the diameter of this tiny tool is more crucial than many realize. It influences everything from aesthetics to utility and, perhaps most importantly, safety.

The Everyday Importance of a Tiny Dimension

Consider the aesthetic impact. A toothpick too thick can appear clumsy and out of place accompanying a delicate hors d’oeuvre.

Functionally, a toothpick’s diameter dictates its strength and flexibility. A toothpick with too small of a diameter might easily break under pressure. This could render it useless for its intended task.

Safety is paramount. A splinter from a fractured, undersized toothpick can cause irritation or even infection. The diameter plays a key role in preventing such hazards.

Debunking Toothpick Myths

This article aims to explore the nuances of toothpick diameter, dispelling common misconceptions. We will explore the factors that determine a toothpick’s size, how to measure it accurately, and why choosing the right diameter is essential for various applications. Get ready to re-evaluate the tiny tool you thought you knew so well.

The previous discussion highlighted the surprising significance hidden within the toothpick’s size. We touched upon how its diameter impacts aesthetics, functionality, and even safety. But before we can delve deeper into the practical implications of toothpick size, it’s crucial to establish a firm understanding of what we actually mean by "diameter."

Decoding Diameter: Understanding the Measurement

The term "diameter" seems straightforward enough. We typically associate it with circles: a straight line passing from side to side through the center of a circle or sphere.

However, when applied to toothpicks, the concept of diameter becomes a bit more nuanced. Not all toothpicks are perfectly cylindrical. Many, in fact, exhibit variations in shape, ranging from slightly elliptical to distinctly square or triangular.

Diameter in a Non-Circular World

So, how do we define "diameter" when our subject isn’t a perfect circle? In the context of toothpicks, diameter generally refers to the maximum width of the toothpick, regardless of its shape.

For circular toothpicks, this is, of course, a simple measurement. But for those with more angular profiles, it represents the greatest distance across the toothpick’s cross-section.

Consider a square toothpick. Its "diameter" would be the length of one of its sides. For a triangular toothpick, it would be the distance from the base to the apex of the triangle.

The Impact of Shape on Measurement

The shape of the toothpick directly influences the method used to measure its diameter. For a circular toothpick, a simple ruler or caliper might suffice.

However, for irregularly shaped toothpicks, more precise instruments are often required.

The challenge lies in consistently identifying the maximum width. This can be tricky with the naked eye, especially for toothpicks with subtle variations in shape. Furthermore, slight imperfections or irregularities in the manufacturing process can further complicate the measurement.

This means that even toothpicks marketed as having a specific diameter may exhibit slight variations when measured accurately.

Why Precision Matters

The need for accurate measurement extends beyond mere academic curiosity. As we discussed earlier, a toothpick’s diameter affects its functionality and safety.

Imagine using a toothpick to dislodge a piece of food. If the toothpick is too thick, it might be uncomfortable or even damaging to the gums.

If it is too thin, it could easily break, leaving splinters behind.

Similarly, in crafting applications, a consistent diameter is crucial for achieving precise results. A toothpick that is slightly wider or narrower than expected can throw off the entire project.

Therefore, understanding how to accurately measure toothpick diameter is essential for choosing the right tool for the job and ensuring both safety and effectiveness. The smallness of the tool does not negate the impact of its dimensions.

The previous discussion highlighted the surprising significance hidden within the toothpick’s size. We touched upon how its diameter impacts aesthetics, functionality, and even safety.

But before we can delve deeper into the practical implications of toothpick size, it’s crucial to establish a firm understanding of what we actually mean by "diameter." With a clear understanding of how to define and measure the toothpick’s diameter, we can explore the materials that influence the toothpick’s characteristics, leading to how each material affects a toothpick’s diameter.

Material Matters: How Wood and Bamboo Influence Diameter

The choice of material profoundly influences a toothpick’s diameter, consistency, and overall performance. Traditionally, wood has been the dominant material, but the rise of bamboo as a sustainable alternative has introduced new considerations.

Understanding the properties of each material is essential for appreciating their impact on toothpick dimensions.

The Reign of Wood: Tradition and its Trade-offs

Wood has long been the go-to material for toothpick manufacturing. Its relative abundance, ease of processing, and familiar feel have cemented its place in history.

However, wood is not without its limitations.

Wood’s Properties and Limitations

Wood’s inherent grain structure and varying density pose challenges to achieving consistent toothpick diameters. Softwoods, like pine, are easier to shape but tend to be less durable and can splinter more readily.

Hardwoods, such as birch or maple, offer greater strength but are more difficult to work with, potentially leading to inconsistencies in diameter during mass production.

Moreover, the direction of the wood grain can significantly affect the toothpick’s breaking point, which is, in turn, related to how thin (or thick) the manufacturer dares to make it.

The Impact of Grain and Density on Diameter Consistency

Variations in wood grain and density directly impact the uniformity of toothpick diameter. A knot or area of dense grain can resist shaping, leading to a slightly larger diameter in that section. Conversely, softer sections may compress more easily, resulting in a smaller diameter.

These inconsistencies, while often subtle, can affect the toothpick’s performance, particularly in applications requiring precision.

Ultimately, wood selection dramatically affects a toothpick’s characteristics.

Bamboo: The Sustainable Challenger

Bamboo has emerged as a compelling alternative to wood in toothpick production. Its rapid growth, renewability, and inherent strength make it an attractive option for environmentally conscious consumers and manufacturers.

But it’s not a perfect substitute.

Bamboo’s Unique Properties

Bamboo possesses unique properties that distinguish it from traditional wood. Its fibrous structure provides exceptional tensile strength, making it less prone to splintering.

Additionally, bamboo’s consistent density allows for more uniform shaping and diameter control during manufacturing. Bamboo toothpicks also tend to be more flexible than their wooden counterparts.

All these factors culminate in a durable, smooth toothpick that is preferred by a growing number of consumers.

Diameter and Consistency in Bamboo Toothpicks

The inherent consistency of bamboo allows for tighter control over toothpick diameter during manufacturing. This results in more uniform products with fewer variations in size and shape.

However, bamboo can also be more brittle than some hardwoods, potentially leading to snapping under excessive force. The specific type of bamboo used and the manufacturing processes employed further influence these properties.

Ultimately, the choice between wood and bamboo depends on a balance of factors. Wood offers tradition and familiarity, while bamboo presents a sustainable and consistent alternative.

But before we can fully appreciate the nuances of toothpick materials, let’s take a step back and examine the sheer variety of toothpick sizes available. The seemingly simple toothpick actually comes in a surprising range of diameters, each suited to different purposes and manufactured using various techniques.

Exploring the Spectrum: A Look at Toothpick Size Variations

The world of toothpicks is far from uniform. While we might perceive them as standardized objects, a closer inspection reveals a diverse landscape of sizes.

From the slender, almost needle-like picks used in delicate hors d’oeuvres to the sturdier, wider versions intended for robust dental cleaning, the range of toothpick diameters is broader than many realize.

This variation is not arbitrary; it’s driven by a combination of manufacturing considerations and, crucially, the intended application of the toothpick itself.

Factors Influencing Toothpick Size

Several factors contribute to the observed differences in toothpick diameter. Understanding these influences provides valuable insight into why certain sizes are preferred for particular uses.

Manufacturing Processes

The methods employed in toothpick manufacturing play a significant role in determining the final dimensions. Automated processes, while efficient, may have inherent limitations in achieving extreme precision.

The cutting, shaping, and polishing stages all contribute to the final diameter, and variations in these processes can lead to noticeable size differences.

Furthermore, the type of machinery used and the skill of the operators also influence the final product’s consistency.

Intended Use: Form Follows Function

Perhaps the most critical factor driving size variation is the intended use of the toothpick.

A toothpick designed for removing food particles from tightly spaced teeth will necessarily be thinner than one intended for holding together a club sandwich.

Similarly, craft applications, such as model building, may require specific diameters for structural integrity or aesthetic purposes.

The intended use directly dictates the required strength, flexibility, and overall dimensions of the toothpick.

Common Diameter Ranges and Applications

While precise measurements can vary between manufacturers, some general diameter ranges are commonly associated with specific applications.

-

Extra-Fine (0.8 – 1.0 mm): These delicate toothpicks are typically used for intricate dental work, cleaning very tight spaces, or holding extremely small hors d’oeuvres.

-

Standard (1.5 – 2.0 mm): This is the most common size, suitable for general dental hygiene and everyday use in restaurants and homes.

-

Wider (2.5 – 3.0 mm): These sturdier toothpicks are often used for holding together larger food items, such as sandwiches or appetizers, or for more aggressive dental cleaning.

-

Specialty (Variable): Craft toothpicks, decorative picks, and other specialized applications may utilize diameters outside the standard ranges, depending on the specific needs of the project.

Understanding these size variations empowers consumers to select the right toothpick for the right job, maximizing its effectiveness and minimizing potential frustrations.

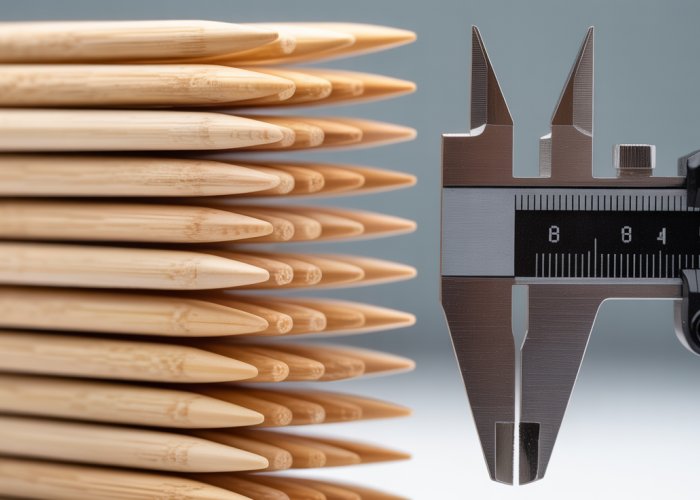

Precision is Key: Measuring Toothpick Diameter Accurately

Having explored the diverse range of toothpick sizes and the factors that influence them, it becomes clear that accurate measurement is paramount, especially when selecting a toothpick for a specific purpose. The naked eye can only discern so much. Determining the precise diameter requires employing specialized tools and techniques.

Tools of the Trade: Calipers and Micrometers

For accurately gauging toothpick diameter, two primary instruments stand out: calipers and micrometers.

Calipers, particularly digital calipers, offer a versatile and relatively user-friendly approach. They consist of two jaws that are brought together to grip the toothpick. The distance between the jaws, representing the toothpick’s diameter, is then displayed on a digital screen. Calipers are suitable for a range of diameters and offer good precision for most applications.

Micrometers, on the other hand, offer an even higher degree of precision. These instruments utilize a screw mechanism to apply pressure to the toothpick, allowing for extremely fine measurements. Micrometers are ideal when minute differences in diameter can significantly impact the toothpick’s performance.

Step-by-Step Guide: Measuring Toothpick Diameter

Regardless of the instrument used, a consistent measurement technique is essential.

- Preparation: Ensure the toothpick is clean and free from any debris that could affect the reading.

- Calibration: Calibrate your measuring instrument according to the manufacturer’s instructions. This is especially important for micrometers.

- Placement: Carefully position the toothpick between the jaws or anvils of the measuring instrument. Ensure the toothpick is perpendicular to the measuring surfaces.

- Application of Pressure: Apply gentle, consistent pressure. Avoid overtightening, which can compress the toothpick and yield an inaccurate reading.

- Reading the Measurement: Record the measurement displayed on the instrument.

- Multiple Readings: Take several measurements at different points along the toothpick’s length. This helps to account for any variations in diameter.

- Averaging: Calculate the average of your measurements to obtain a representative diameter.

Minimizing Error: Ensuring Reliable Results

Even with the right tools and techniques, potential sources of error can creep into the measurement process.

One common error stems from inconsistent pressure. Applying too much force can deform the toothpick, leading to an underestimation of the diameter. Conversely, insufficient pressure can result in an overestimation.

Another source of error arises from parallax, the apparent shift in an object’s position when viewed from different angles. To minimize parallax error, ensure your eye is directly aligned with the measuring scale or digital display.

Instrument calibration is also critical. A poorly calibrated instrument will inevitably produce inaccurate readings. Regularly check and calibrate your calipers and micrometers according to the manufacturer’s guidelines.

Finally, consider the shape of the toothpick. If the toothpick is not perfectly round, measuring the diameter at different orientations will yield varying results. It’s best to take multiple readings across the toothpick’s cross-section and calculate the average.

By understanding the tools, mastering the techniques, and diligently addressing potential sources of error, achieving reliable and accurate toothpick diameter measurements becomes attainable.

Form Follows Function: When Toothpick Diameter Matters Most

Having established the means to accurately measure toothpick diameter, it’s time to consider why this measurement matters. A toothpick is not simply a toothpick; its dimensions dictate its utility. The diameter directly correlates with the toothpick’s suitability for various tasks, influencing its strength, flexibility, and overall effectiveness.

The Symbiotic Relationship Between Diameter and Intended Use

The diameter of a toothpick is not arbitrary. It’s intrinsically linked to its intended application. A toothpick designed for dental hygiene will differ significantly from one used for culinary purposes or crafting. The ideal diameter optimizes performance for a specific task, balancing strength, flexibility, and maneuverability.

Consider the implications: a toothpick too thick for flossing might damage gums, while one too thin may break under minimal pressure when holding together a club sandwich. Understanding this relationship allows for informed selection, maximizing efficiency and minimizing potential issues.

Size Variations and Their Impact Across Scenarios

Toothpick size variations dramatically affect their effectiveness in diverse applications. The delicate balance between strength and flexibility hinges on the diameter, impacting the toothpick’s ability to perform its intended task.

Dental Hygiene: Precision and Safety

For dental applications, a thinner diameter is generally preferred.

This allows for easier navigation between teeth and minimizes the risk of gum irritation. However, the toothpick must still possess sufficient strength to remove plaque and debris without snapping.

A diameter range of 1.8mm to 2.0mm strikes this balance well.

Culinary Creations: Strength and Presentation

In the culinary world, toothpicks often serve as skewers or fasteners for hors d’oeuvres.

Here, a slightly larger diameter is advantageous.

Increased strength is needed to support heavier food items and prevent breakage.

A diameter of 2.0mm to 2.5mm typically works best for holding together sandwiches, olives, or fruit skewers.

Additionally, a larger diameter can enhance the toothpick’s visual presence, contributing to the overall presentation of the dish.

Crafting and Model Building: Detail and Stability

For intricate crafts and model building, the ideal toothpick diameter depends on the scale and complexity of the project.

Smaller, more detailed work may require very thin toothpicks (around 1.5mm or less) to allow for precise placement and avoid obscuring fine details.

Conversely, larger models or structural elements may necessitate thicker toothpicks (up to 3.0mm) for added strength and stability.

The choice of diameter directly impacts the structural integrity and aesthetic appeal of the finished product.

Specific Uses and Ideal Diameters: A Practical Guide

To further illustrate the importance of diameter, consider the following examples:

-

Cocktail Garnishes: Thin toothpicks (1.6mm – 1.8mm) are ideal for skewering small fruits or olives, providing a delicate and unobtrusive presentation.

-

Sandwich Assembly: Medium-diameter toothpicks (2.0mm – 2.3mm) offer the necessary strength to hold sandwich layers together without being overly bulky.

-

Architectural Models: A range of diameters (1.5mm – 3.0mm) may be needed, with thicker toothpicks used for structural supports and thinner ones for detailing.

-

Dental Picks: Thinner toothpicks made of softer wood like birch are useful to promote teeth and gum health. The soft wood adapts to tooth gaps without causing damage.

In conclusion, the "perfect" toothpick diameter is not a fixed value. It is a variable dependent on the toothpick’s intended function. Recognizing this crucial relationship allows for a more informed and effective use of this ubiquitous tool. By understanding the interplay between form and function, users can select the toothpick that best meets their specific needs, maximizing its potential and minimizing frustration.

Toothpick Diameter: Frequently Asked Questions

Here are some common questions regarding toothpick diameter and its significance.

What’s the typical diameter of a toothpick?

While not strictly standardized, the diameter of a toothpick usually falls between 2.0 and 2.5 millimeters. This range provides sufficient strength for its intended uses.

Why does toothpick diameter matter?

The diameter affects the toothpick’s strength and usability. Too thin, and it breaks easily. Too thick, and it might be uncomfortable or difficult to use in tight spaces.

Are all toothpicks the same diameter?

No, there can be slight variations in the diameter of a toothpick, even within the same brand. Manufacturing processes and material variations can cause these subtle differences.

Does the material affect the ideal diameter of a toothpick?

Yes. A toothpick made of a weaker wood might require a slightly larger diameter for sufficient strength than one made from a stronger material like bamboo. The density of the material plays a significant role in determining the ideal diameter of a toothpick.

So, there you have it! Hopefully, you’ve got a better grasp on the diameter of a toothpick and why it actually matters more than you might have thought. Now go forth and floss—or, you know, carefully use a toothpick—armed with this newfound knowledge!